|

Uncommon British plugs and sockets |

BS1363 |

other specials |

|

|

|

|

| ↑ | ↑ | ↑ | |

|

|

|

| 1, 5 | 13A, non-standard socket and plug for use on installations requiring restricted access (medical equipment, computers etc.), or a special type of earthing (see no. 2). Because of the T-shaped earth pin, non-standard and standard BS 1363 devices cannot be mixed. Brand name: MK Electric. |

| 2 | Both non-standard sockets nos. 1 and 3 have two independent earth terminals. The image shows at left a conventional terminal, linked to fixing screws, and a 'clean earth' terminal at right, linked to the earth pin. The socket can be used for 'clean earth' as well as conventional earth installations. Depending on the installation the green/yellow earth wire link has to be removed; see details on clean earth given below. |

| 3, 6 | 13A,

non-standard

socket and matching round pin earth plug. Meant for comparable purposes

as nos. 1 and 5. Manufacturer Midland Electric Manufacturing Co. (MEM). The switched socket has a neon indicator light. |

| 4, 7 | Wandsworth

non-standard socket and plug with pin configuration identical to nos. 3

an 6. Wandsworth is the UK's oldest independent manufacturer of

electrical accessories. It is unclear which company has originally

designed this plug with a round earth pin for applications where a

non-interchangeable facility is necessary. Note the characteristic typeface of the Wandsworth company name. |

|

|

|

|

|

|

|

|

| 8, 9 | Outlet and plug for AC electric

wall clocks,

manufactured by MK Electric. The low profile of outlet and plug allows placement hidden

behind a sufficiently large clock. Image no. 9 shows the outlet without

clock

plug (see no. 10). Manufacturer: MK Electric. {ASw} |

| 10, 11 | Electric clock plug, equipped with a retaining screw to prevent accidental disconnection. Image no 11 shows an enlarged view of the reverse side of the plug, with a BS 1362 2A fuse and three small, flat blade pins (line, neutral and earth). {ASw} |

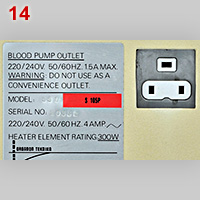

| 12 - 15 |

Walsall

gauge socket and plug. Plug No.13: {ASw} Compared to pin orientation of BS 1363 plugs each of the Walsall pins is 90 degrees rotated. Line feed is protected by a 13A BS 1362 fuse. For obvious reasons the plug bears a NOT FOR DOMESTIC USE notice. Image no. 14 shows a part of a dialysis machine. The Walsall socket was used so that only an approved appliance for the machine (blood pump) could be used. Walsall plugs have also been used for local power supply backup networks and can still be found at some London Underground stations, see images 16a/b below. Image no. 15 shows the name Walsall on an older (pre-1994) plug [top] and a modern (= image no. 13) model [bottom]. |

| Photo no. 14 (dialysis machine and Walsall socket) has been copied, with permission, from Robmcrorie's Photostream; see https://www.flickr.com/photos/robmcrorie/6539260819 for the original image. |

|

|

Photo taken at London Underground Bond

Street station (Jubilee level). Despite tape on the socket it is clearly visible that it is a Walsall type outlet. Two possible reasons for choosing non- standard sockets at Tube stations are: (1) preventing that the public (mis)uses the London Underground electricity network; (2) the outlet is connected to a centre-tapped 110V circuit; for safety reasons a mandatory practice on construction sites in the UK. The photo has been taken in 2011 by Alastair Swaffer under difficult conditions in a very busy platform. |

|

|

|

|

|

|

|

| 17 | Non-interchangeable,

unswitched, earthed twin socket for 'key plugs' (see nos. 20-22). The

plugs have to be rotated 90 degrees to make contact, a procedure that

restricts accidental removal. These Electronic Point of Sale (EPOS)

plugs and sockets are frequently used in shops, where they are

connected to tills etc. There also exists a similar, blue, UPS version meant for a local network with an Uninterrupted Power Supply. A third, white, version is prepared for clean earth wiring (see explanation below). The use of proprietary plugs and sockets prevents unauthorized use of outlets in public spaces. Brand name: Electrak, Consett, England. The company is a part of the Legrand group. |

| 18 | Each

outlet has

a shutter that is pressed down by inserting a key plug (see no. 20).

The image shows a

shutter that has

artificially been kept in a down position to show the three slits that

give access to the contacts. |

| 19 | Two steps

to engage a plug. 1: insert plug fully; 2: rotate plug 90 degrees

clockwise. Follow reverse procedure to disengage plug. |

| 20 - 23 |

EPOS key

plug. A stack of three brass plates makes contact with strips in the

slits shown in image no. 18. The earth plate is positioned in an

advanced position (see no. 21), what allows making contact first.

The neutral pin has a projection, set forward of the pin itself, known

as the nib. Also the neutral pin of the UPS variant has a nib, but on

the clean earth variant it is the line pin that has a nib (see white

plug no. 22). The nib

device makes clean earth plugs non-interchangeable with EPOS and UPS

sockets (vice versa). Plugs are fused with a BS 1362 13A, 5A, or 3A

fuse (see image no. 23). The clean earth plug (no. 22) has been donated by {GF}. |

| note |

Above shown key plugs and sockets comply with BS 5733. This British Standard specifies requirements and tests to check the safety in normal use of electrical accessories which are not covered by other specific British Standards. |

|

|

|

|

|

|

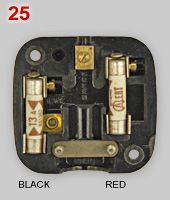

| 24, 24a 25 |

Britmac

special plug rated at 13A, but without notification of voltage. The

original package mentions 110V*. Both power poles (designated as L and

N) are fused with standard BS 1362 fuses. 110 Volt equipment is

mandatory for transportable tools on construction

sites to reduce

electrical shock hazards. An often used 110V transformer is shown in

figure 26. {ASc} * image 24a, taken by Michael Gilligan, shows a similar Britmac plug with an engraved and paint-filled 110 VOLTS. The plug indicates that a red flex cord has to be connected to the line pole, black to neutral and green to earth. In the early 1970s these colours have been changed to respectively brown, blue and yellow/green. This means that the plug dates back to the 1960s or earlier. Other dated features are an earth connection inspection hole (not shown), the inscription "BSS 1363 where applicable" (British Standard Specification, rather than BS) and not insulated L and N pins. The package has a Dorman Smith Britmac Ltd. catalogue number AP 14DP (finish 519-9387), which indicates that the plug dates back to the years when Britmac was a merged with Dorman and Smith. Find more about Britmac at the FCU page. |

| 26 | 110V

transformer with an earthed center-tapped secondary winding. It ensures

that the

voltage to earth should never exceed 55 Volt. Circuits that differ from

240V must have sockets and plugs that are non-interchangeable with

standard 13A-240V BS 1336 to prevent misconnection. Nowadays yellow BS EN 60309 (IEC 60309) 100-130V plugs are commonly used. Drawing is based on Figs. 6.8 and 7.5 in Technical Section of TLC Electrical Supplies guide. |

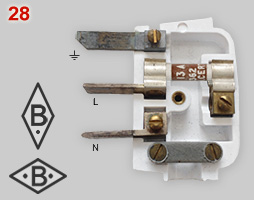

| 27, 28 | Britmac

non-standard socket and plug for domestic use, rated at 13A - 250V. L,

N and earth pins are flat blades. Approximate sizes are: 15 mm (L, N),

18 mm (earth) long and, 6 mm wide. Pin spacing is ca. 15 mm. The

socket, depicted without wall plate, has shutters that are

pushed aside by the longer earth pin. Socket has No. 1285, plug has

Reg. No. 904291. {SR} Additional information by Simon Rogers: Britmac sockets were already in the house in East Sussex when the Rogers family moved in (1975ish). Single, double and probably also quad sockets have existed. It is likely that the main advantage of the Britmac type was to allow two outlets in the space of a single 13A MK socket. Note the two Britmac logo variants: horizontal diamond, with two dots (socket) and vertical with a single dot (plug). |

|

|

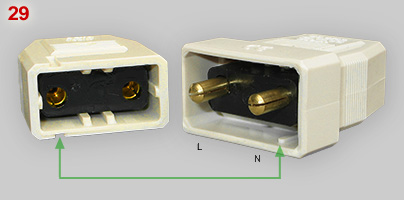

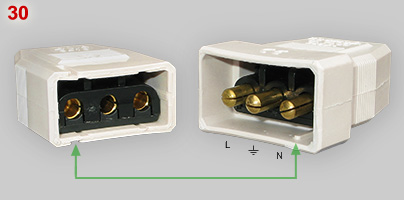

| 29, 30 |

BS 5733 2-pin (line and neutral) and 3-pin (L, N and earth)

flex connectors. The male connectors

do not have a fuse because extension cables are connected to the main

electrical circuit by a fused BS 1363 plug. Both 2 and 3-pin flex

connectors are non reversible, because of the ridge and indentation in

the housing of respectively the male and female plug (green arrows).

Moreover, the pins are positioned off-center in their housing. A 2-pin

male plug does not fit in 3-pin female plug, because of a difference in

off-center positioning. The 2-pin version is rated at 10A;

the 3-pin version at 5A. Manufacturers: Deta Electrical Comp., Luton, UK (no. 29) and Lyvia Electrical Ltd, Harlow, Essex, England (no. 30). |

| Clean earth socket. The 16th edition of the IEE Wiring Regulations (BS EN 7671 amendment No.2) require the fixing screws of all mains sockets to be earthed. This is normally achieved by a link that connects a metal insert in the fixing holes of the socket to the earth pin connection. If a metal back-box is used that is in contact with the building earth, a large amount of current can flow through this path if there is a significant difference in potential between the earth reference bar (ERB) and the building earth at that point. This problem is more likely to occur in an old building where there may be a link between earth and neutral somewhere in the wiring. The fault current can inject large amounts of noise into the equipment that is being fed from the supply. This may interfere with sensitive medical equipment. The problem can be reduced by eliminating the current path between the ERB and the building earth provided by the earth connection in the mains socket. This can be done by replacing the metal back-box by a plastic one, or by fitting a clean earth socket. |

A clean earth socket has two separate and isolated earth connections – one which goes to the earth pin rcontacts of the sockets, and the other which goes to the fixing screws. The connection to the earth pin contacts should run via a separate cable, back to the earth reference bar (ERB). The fixing screws make contact with the structural earth via the body of the metal junction box and so may have a different potential to the ERB. Therefore a separate earth is connected to this ‘dirty’ connection and also returned to the appropriate point on the ERB. Image, see: Clean earth 3 terminal socket (link). |

|

BS1363 |

|

|

|

specials |