|

Classic continental European Plugs with additional features |

| Several types of not earthed, special

plugs have been

designed, as: - plugs equipped with an on/off switch (nos. 7-11), - plug with internal fuse (no. 12-14), - plugs with a provision for switching between 125 and 250 Volt networks (nos. 15-23). |

| A short introduction may help to

understand the switch mechanism that was used in plugs designed up to

1950s. |

|

|

|

|

|

|

|

|

| quick-break AC and DC |

Image

nos. 1 - 4 show rotary switch mechanisms of light switches. The central

rotor carries a metal bridge that can make or break the connection

between the wire contacts at both sides of the rotor; compare

images no. 1 and 2. It is important that making and breaking

contact happens quickly to minimize electric arc formation. Heating by

arc formation will damage the contacts and shortens switch life. A

fast-moving rotor has a spring-operated mechanism; see spring around

the central axis of switch no. 3/4. Arc formation is more prominent in direct current than alternating current circuits. AC current periodically passes through zero. The larger the contact zones, the longer a switch remain serviceable. Small point contacts (see no. 5/6) are not suitable for DC. From the late 19th century electrification was carried out by local or regional companies that exploited DC and AC networks. Country-wide operating AC electricity networks arose from the 1950s. |

| 1, 2 | Very common type of rotary switch mechanism that for about half a century has been used for both DC and AC light switches. The shown example has been made by Ernst Maté in Wien (Vienna, Austria). Dating: 1920s. {RH} |

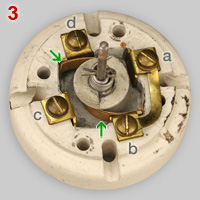

| 3, 4 |

Alternative

type of rotary type light switch of both DC and AC. Two,

interconnected, sets of

flexible blades are connected to the rotor. The switch has four wire

connections (a-d). 'a' and 'b' are interconnected. Depending on the

position of rotor position 'a/b' is connected to 'd' (image no. 3), or

'c' (no. 4). Unknown origin. Dating: possibly 1910s.

{YG / FS} |

| 5, 6 |

Tumblet

type switch that is only suitable for AC, because of the small contact

points (ca. 7 mm2).

The photo shows the switch of a combined Schuko socket, made by

Stotz-Kontakt in Heidelberg. The company

dates back to 1891 and merged

in 1968 with Busch-Jaeger in Lüdenscheid. Dating of switch/socket:

1950s. |

|

|

| |

|

|

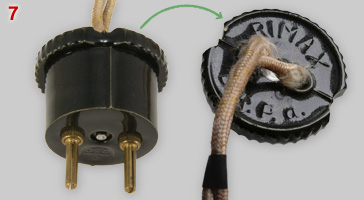

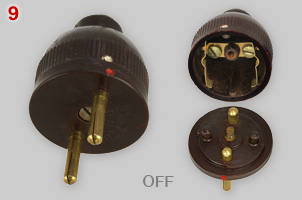

| 7, 8 9, 10 |

Steatite

plug with integrated switch, rated at 6A-250V. The top, ribbed disk is

rotatable to switch the connection on and off. Name of manufacturer or

trademark: Rimax. Partly visible: D.R.P.a. (Deutsches Reichs Patent

angemelded = patent pending).

Dating: 1930s or earlier. (RH} Switchable, Bakelite plug, rated at 6A-220V. Manufacturer: Ewald Mund (Heidelberg). Dating: late 1940s - early 1950s. {RH} The leaflet shown right states that "Thousands of accidents and anxious seconds each year because of damaged electrical devices or inferior installations. Therefore you have to buy immediately a 2-pole safety plug* that can be switched off for each appliance used at home, company, business etc." * by Ewald Mund marketed as "safetyplugswitch". German patent was applied (D.P.a. = Deutsches Patent angemelded), but it is unclear whether a patent has been granted since similar, older plugs have existed. For plugs 7 and 9 applies that speed of breaking contact largely depends on the quickness of manual rotation. |

|

|

11 | Bakelite plug with a push-type switch. Rating: 6A - 250V AC. Unknown origin; no marks or certification. Dating: 1960s. {WN} To make contact push plug firmly down (4.5 mm). The red knob pops out. To break contact press the knob and the plug housing moves up quickly. Pins remain in contact with socket contacts. |

|

|

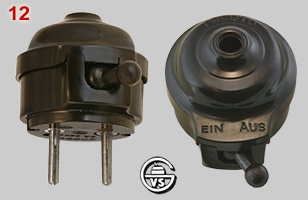

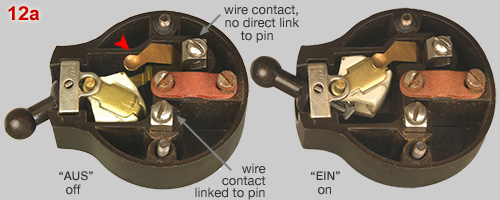

| 12 |

Bakelite 2-pin plug rated at 6A - 250V with a single pole

tumbler switch. Switch mechanism is explained in image 12a. Manufacturer: Presto (Presto-Vedder GmbH in Schalksmühle). Dating: mid 1930s. {RH} |

| 12a | Image

12a-left shows that the top wire contact has a flexible brass

contact strip (red arrow). A second contact strip is visible further

down. The lower strip is connected to the top pins (= left pin in

image 12). The tumbler switch lever moves the white vitreous block with copper strip from off-position (image left) to on-position (image right). In on-position the copper strip connects the top flexible brass strip with the lower brass strip. Pin is now connected to wire contact. A spring (not visible) keeps the vitreous block in either off- or on-position. |

|

|

|

|

| 13 14a, b |

Handmade

ebonite plug with fuse inside (green arrow). This type of plug has been

made from early 1900s to mid 1930s. The shown plug is probably a 1900s

model, because cords enter at the side. Later models had a cord entry

at the top of the ball shaped grip. Ebonite is black, but slowly lose

colour and finally may have a timber-like colour. None of the 2-pin plugs were (and still are) polarized. It is likely that the groove in the bottom plate has been made to mark the fused pin (if the round plate is correctly mounted). The origin of this quite rare plug, that has no marks, is unknown. Originally, the brass wire-fuse* had a score halfway to make a defined breaking point that avoids burning a contact. * the brass wire of the shown plug had to be a fuse, but it is an ordinary brass replacement wire. To replace fuse wire, (1) unscrew pins, (2) unscrew top and left round nuts and (3) remove burned out fuse and wire a new fuse around each of the screw threads. {RH} |

|

|

15 1910s porcelain Siemens-Schuckert plug with unequal pin diameters. Rating: 6A-250V. Although not indicated, the plug is probably designed for Direct Current. For DC electro-motors correct + and - pole connection matters. Plug has a round recess (arrow) between the pins. Recess diameter = 5.0 mm; depths 5.2 mm. It is likely that the matching socket (not in collection) had a pilot pin in between the contact holes; see image 16. 16 Schuko socket for similar (but earthed) plugs with unequal pins. The pilot pin prevents using inadequate plugs. See uncommon Schuko page for details. |

|

|

|

|

|

|

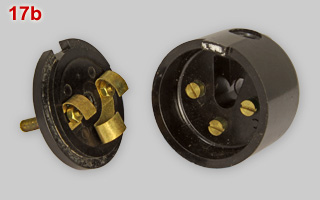

| 17 17a, b |

Classic

French BI-TENSION plug allowing to switch between 125 and 230 Volt. Image no. 17: top view; no. 17a: side view; no. 17b: inside view with contact clips (left) and screws to connect wires (right). By releasing the large central screw (red arrow in image no. 17a) the base plate with pins can be mounted in two positions (see image nos. 18 and 19). The excentric, white screw serves as cord grip. The text "BREVETÉ S.G.D.G" means that the plug is guaranteed by the manufacturer, but this guarantee is not recognized by the government (Sans Garantie Du Gouvernement"). In France it was until 1968 a common way of indicating a patent. Testing of functionality, safety etc. by the manufacturer was not compulsory and a warranty that the manufacturer will repair or replace the article in case of a fault was not included. Dating of plug: probably 1950s. |

| 18 - 19 |

Image no.

18: 125 Volt pin position and 'active' wires. Note that blue and red

wire are connected to the same pin. Image no. 19: 230 Volt pin position. The green wire is not connected to any pin. |

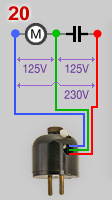

| 20 | Bi-tension

plugs were used for small motor-driven application, for example an

electric razor. The scheme shows how a 125V razor motor (M), in

combination with a second voltage 'consumer' can be used for 125V or

230-250V. The second 'consumer' was often a capacitor, but also

little bulbs or heaters have been used. It is important that the left

and right 'consumer' have the same operating power (Watt). The circuit

is a cheap and less heavy alternative to a transformer, but the

disadvantage is that half of the energy is wasted. I am grateful to Reiner Hahn for giving details

about the use of bi-tension plugs.

|

|

|

|

|

|

|

|

| 21, 22 |

Plug with

switch

between 127 and 220 Volt. Capacitor (see scheme no. 20) and other

electronics are incorporated in plug housing. Unknown origin. Dating:

late 1950s. {WN} |

| 23 | Plug of a Philishave razor with switch between either 110-130 Volt or 180-220 Volt AC or DC. It came probably with a twin head shaver made by the Philips company (Eindhoven, Netherlands) in the 1950s. {WN} |

note |

Modern multi-voltage plugs have electronics that automatically recognize local voltage (100-240 V, 50-60 Hz) and adapt plug output accordingly. Depending on local sockets, the only incompatibility that may remain is plug pin or blade configuration. |

| 24 - 27 | Plug

with a detachable connector. The possibility to detach one of the

connections facilitates Christmas tree illumination with a chain of

lights. The plug fits in both Schuko and not earthed sockets. Rating:

10A - 250V. Manufacturer: Joseph Müller, Presswerk in Nürnberg,

Germany. {RH} |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |