|

Crater adaptable plug for BS round pin gauges |

BS 546 |

Fitall |

phased out |

|

Crater adaptable plug for BS round pin gauges |

BS 546 |

Fitall |

phased out |

| Images of the Crater plug are based on

photos provided by Lucien Nunes.

Most of the

information comes also from his hand. The plug is displayed in the

Electro-mechanical Museum, Electrokinetica. About a year after completing this page the museum could buy a Crater plug, fully identical to the specimen shown below. |

| The Crater adaptable plug was designed to

fit the six standard sizes of British round-pin socket outlet in

general use: 3-pin 2A, 5A and 15A types to BS 546, and the 2-pin 2A, 5A

and 15A types to BS 372 part 1. Although the pin gauge is identical on

2-pin and 3-pin variants of the same current rating, the pins are

spaced more widely in the 3-pin configuration. Unlike the later Fitall plug,

which required the user to squeeze the plug to fit 2-pin

configurations, the Crater plug has independent sets of pins for all

six types. |

Crater plugs are rare. Details about the

manufacturer are unknown, possibly it is the same company as Crater

Controls Ltd; both resided in Woking, Surrey. When production has

started and ended is unknown too (1930s - 60s?). Tracing the UK patent

no. 8376/47 has failed up to now. Probably Crater plug are mostly used

by electrotechnical repairman. The plugs are ideal when equipment has

to be used with sockets that may differ from place to place. The

alternative would be carrying a set of six adaptors. |

|

|

|

|

|

|

|

|

| 1 | Side view

of a Crater plug. Dimensions are: ca. 60 mm in diameter and 50 mm high.

Rating: 2-15A - 250 V. Bakelite housing. |

| 2 | Upside down view, showing the in guide plate (disc 1, see image 5a) with holes for each of the 15 pins (see images 7a-9b). |

| 3 | Exploded view showing the plug body, with 15 pins inside, the base plate (disc 1) and a selector disc (disc 2, see image 5b). |

| 4 | Fifteen pins are kept in position by five copper plates which are in direct contact with the line, neutral and earth screw terminals (see image 6). |

| 5a | Pin guide

plate. Unlike the selector disc (image 5b) the guide plate can't rotate. |

| 5b, c |

Selector

disc, with a knurled ring, sandwiched between the plug body and the

pin guide plate, to allow only one set of pins to slide out at a time.

A spring-loaded ball creates definite click positions for each setting,

aligning with markings on the base of the plug (see image 5c). The

selected pins are locked in position by screwing them anticlockwise

until tight. Unselected pins are not electrically isolated but are

trapped inside the plug body when in use, to prevent accidental

contact. Results of the six possible selections are shown in images 7a

to 9b. |

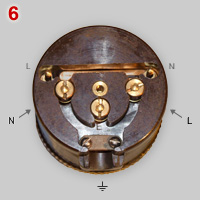

| 6 | After

removing the top cap (see image 1) three screw terminals to connect

a flex become visible. The L and N contact pins, indicated in grey

lettering are internally connected to the matching screws. |

|

|

|

|

| ↓ | ↓ | ↓ | |

|

|

|

| 7a, b |

2A, two

and three pin configurations. |

| 8a, b |

5A, two and three pin configurations. |

| 9a, b |

15A, two

and three pin configurations.

Comparison of images 9a and 9b clearly shows that the spacing of the

lower two pins (line and neutral) is a bit wider in the earthed plug

(9b) than in the non-earthed plug (9a). A comparable difference in

spacing also exists for 2A and 5A plugs. |

notes |

Because of the compact size of many 2-pin socket outlets, the three pairs of pins to suit these (images 7a, 8a and 9a) are arranged around the outside edge of the plug, enabling it to fit most sockets provided there is reasonable clearance to at least one side of the socket for the plug body to project. However the pin sets for 3-pin sockets (images 7b, 8b and 9b) are located centrally, therefore due to the large diameter of the plug it will not fit certain 2A and 5A 3-pin sockets such as those with projecting switch toggles and side entry types with the earth contact close to the mounting surface. It will however fit most 15A sockets. Because the 2-pin plug variants are non-polarised, the Crater plug was not intended to provide a definite polarity to the equipment. This has been exploited in the layout of the pins, where the 5A 3-pin configuration connects the flex to the socket with reverse polarity by comparison with the 2A and 15A. |

| D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |