|

Appliance connectors notes about precursors of IEC 60320 |

info page |

IEC 60320 |

| A

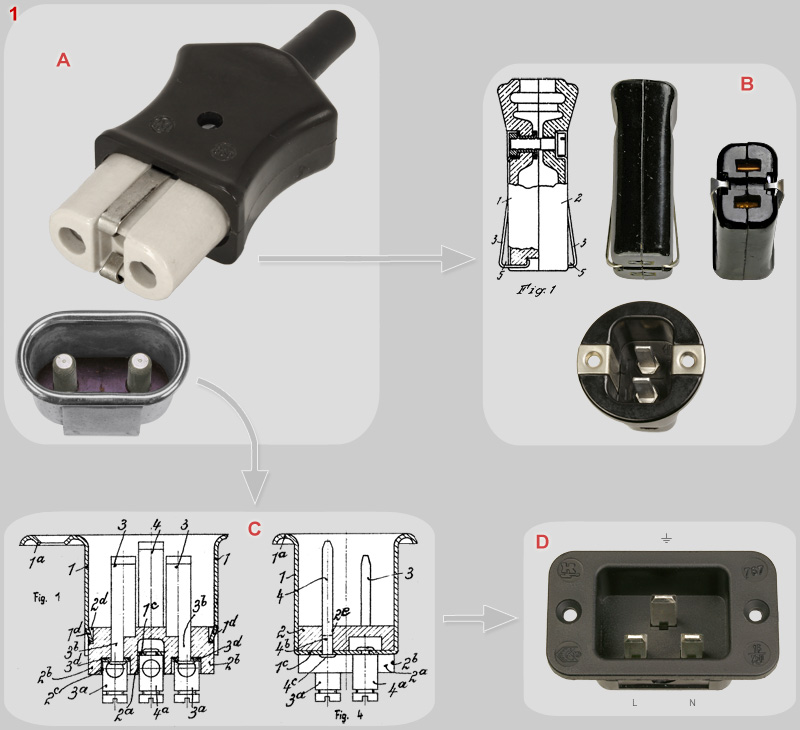

1959 German patent granted to Fa. Leopold Kostal shows features that

are characteristic for IEC 60320 appliance couplers types C9

to C24, introduced in 1970. The image below places IEC 60320 in

historical background. Elements in the image are

displayed in scale. Essential information has been provided by Reiner Hahn. |

|

| 1A. Appliance connector and inlet according to DIN-VDE 4990. The standard became effective in 1920 and was later replaced by the essentially identical DIN 49491. Metal case of the inlet and connector earth clips provides for the possibility to ground the appliance. ABL, Felmas and Siemens were among the first companies to use the method of grounding by earth clips. 1B. Fig. 1, taken from Siemens-Schuckertwerke patent DE000001434367 (1936). It shows that already mid 1930s a small type of appliance coupler existed with earth clips and flat blade power pins. The shown black connector and matching inlet date back to the 1950s and have been made by the German company Kautt & Bux. Flat pins rather than round pins have been chosen to maximize pin spacing in a small size appliance coupler. A larger pin spacing reduces the risk of arc formation when power is connected or broken. Small size inlets, applicable up to ca. 6A, have the additional advantage that it is impossible to touch pins under tension when a connector is not fully plugged in. Pins of much larger DIN-VDE 4990 inlets can be (indirectly) touched. Legend to Fig. 1. 1 and 2: two halves of (Bakelite) plug cast; 3: metal earth clip; 5: free space between clip and cast that allow clips to be compressed when the connector is inserted into an appliance inlet. |

1C. Figs. 1 and 4 taken from patent DE1095911, applied in July 1959 by Fa. Leopold Kostal in Lüdenscheid, Germany. The drawings show an appliance inlet based on DIN-VDE 4990. However, it has three flat blade pins; two power pins and an additional earth pin. The metal cap is no longer a part of the earth connection. In the past appliance cords have regularly been misused as a flex cord; see image 3, below. Inlets with flat blade pins can't be used improperly, a significant safety improvement. The three pins are arranged in a non-equilateral triangle, which means that there is only one way to plug in the connector. In contrary to 1A and B, the Kostal design is polarized. The inlet has been designed for integrating into equipment. Image 2 shows a matching appliance connector. Legend to fig. 1: front view and fig. 4: side view. 1: metal cast; 2: steatite (soapstone) base; 3: flat blade power pins and L, N wire contacts; 4: flat earth pin and wire contact. The earth pin is longer than power pins, in order to make ground contact first. 1D. IEC 60320 C20 (16A) appliance inlet. The IEC standard has been introduced in 1970 as IEC 320. Except materials used, C20 inlets are very similar to the inlet patented by Leopold Kostal (see scheme 1C). Although an official statement about the relation between IEC and Kostal inlets has not been found, it is likely that the IEC 60320 standard has been inspired by patent DE1095911. Each of the IEC 60320 6A, 10A and 16A appliance couplers have flat blade pin configurations. |

|

2. Bakelite appliance connector with steatite contact part, rated at 10A-250V. Manufacturer: Swiss, still existing, company founded by Adolf Feller in Horgen (AFH). Bottom right: IEC 60320 C22 inlet. The connector has a mix of characteristics of appliance couplers shown in image no. 1: • model is more alike DIN 49491 (1A) than IEC connectors; • flat blade contacts are identical to Kostal patent (1C); • model has slanted steatite sides and fits in both IEC 60320 16A inlets: common C20 (1D) and 155º C22 inlet (2), but • model is rated at 10A. Conclusion: the Swiss connector is a DIN 49491 to IEC 320 transition model that dates back to the 1970s-'80s. The AFH logo with five pointed star was used until ca. 1990. |

|

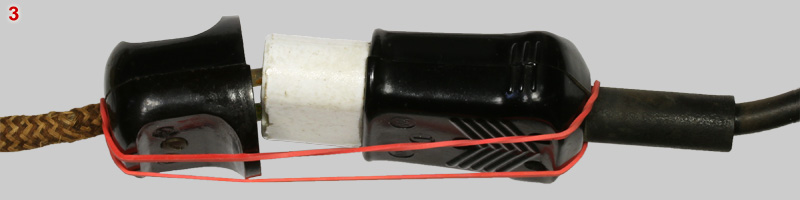

| 3 | 6A

plugs of 1930s flex cords had 4.0 mm pins (left plug). Upgraded 10A

plugs still had 4.0 mm pins, whereas earthed Schuko plugs always have

had 4.8 mm pins. Contacts of

DIN-VDE 4990 connectors (right plug) are dimensioned for 6.0 mm inlet

pins (see image 1A above). Both plugs with 4.0 and 4.8 mm pins cannot make stable contact with DIN-VDE 4990 or 49491 appliance connectors. Nevertheless, appliance cords were frequently misused as flex cords. One of the tricks was using a rubber band to force contact between pin tip and the too wide connector contact. Clearly a most unsafe situation. An effective earth contact is never possible because earth clips of a Schuko plug and DIN-VDE 4990 connector cannot touch each other. Although special adapters for appliance connectors have been designed, see images below, they have never been used on a large scale. |

|

|

|

| 4 | Adapter to

convert a non-earthed appliance cord to a flex cord that can be used

safely

for plugs that have 4.0 mm pins.

The adapter has been made by Willy Buschhaus, Fabrik für

elektrische Erzeugnisse in Lüdenscheid, Germany and probably dates back

to the 1930s. {RH} |

| 5 | Basic,

non-earthed adapter for appliance connectors, made of a more modern -

than Bakelite - thermosetting plastic. Rating, certification mark and

logo of manufacturer are lacking. Dating: 1960s. {WN} |

| 6 | 3-way Schuko (CEE 7/4) multi-plug with appliance coupler inlet. Rating: 10A - 250V. Manufacturer: Gebrüder Broghammer, Uhrenbestandteile und Elektroapparate, in Schramberg, Germany. Dating: 1950s. {RH} |

|

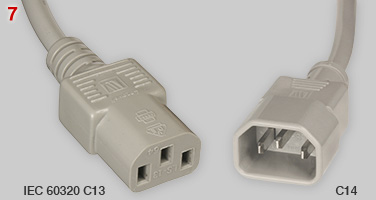

7 Most IEC 60320 cords have an appliance connector on one side and a domestic wall plug on the other side, but extension cords with a C13 connector and a C14 'male' plug exists also. Adapters comparable to nos 4-6 shown above do not exist. |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |