|

Plug pin - Socket connection adaptations to improve stable contact |

General info |

| The crucial aspect of plug - socket

connection is a reliable contact

between plug pins and socket contacts. Reliable means a stable contact

over a sufficiently large area to guarantee a safe and undisrupted

power circuit. Most early socket contacts were simple tubes; plugs had solid round pins, see images 1 and 2. Tube inner diameter and pin diameter has to match exactly. Accepted tolerances in diameters were in the order of magnitude of less than a millimeter. Not really a problem if plug and socket were made by the same manufacturer, but in practice sockets are used for appliance plugs of different origin. Quite a number of adaptations of round plug pins and socket contacts have been designed. See images 3 - 15. For straight blade and rectangular pins it is more simple to construct a reliable plug - socket connection; see images 16 - 27. Most examples show domestic plugs and sockets. |

| Basic round pin

plugs and

sockets contacts |

| 1 | 2 | 3 | 4 | |

|

|

|

|

|

| 1 | Classic

porcelain plug with two solid round pins. Pin diameter: 3.85 mm. Dating: 1900s - 1910. Manufacturer is not indicated. |

| 2 | Classic socket with porcelain base and brass tubes, with 5.57 mm inner diameter. Manufacturer: General Accessories Co Ltd, Bristol, England. Dating: 1900s- 1910s |

| 3 | Plug with split pins

that allow some adjustment of pin diameter. Split pins were

introduced in the early 20st century. For half a century it was the most commonly used pin

adaptation. Enlarging split size with a screwdriver or knife resulted occasionally in breaking off a pin half. Pressing the pin halves firmly together resulted in a too small pin diameter to make stable contact. Split pins were gradually phased out and nowadays solid pins are mandatory in all applicable standards. Manufacturer: Felmas, Leipzig, Germany. Dating: late 1920s - early 1930s. |

| 4 | Socket split

tubes have existed also. They were much less effective than split pins,

because of the relative small length of the tube contact zone. Manufacturer: made in England

by unknown company. Dating: 1930s (?). |

| Examples of improvements of plug pin and socket tube-type contact designs |

| 5 | 6 | 7 | 8 | 9 | 10 |

|

|

|

|

|

|

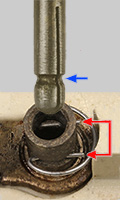

| 5 | Socket

tube with a flexible clip, partially inside the contact zone (red

arrows). Clips grab the circular indentation of the plug pin (blue

arrow). A very stable plug - socket connection, but mainly used for

(light) industrial appliances. Dating: 1920s. Manufacturers: Siemens-Schuckertwerke, Berlin, Germany (plug); Voigt-Haeffner, Frankfurt a.M., Germany (socket). |

| 6 | Socket

with construction that presses a plug pin firmly toward the tube inner

side (5.5 mm diameter). Allows the use of plugs with quite a range of pin diameters.

Found only on sockets made by the Danish company Lauritz

Knudsen. Dating: 1980s (?) |

| 7 | Socket with

construction comparable to socket no. 6, but a more simple design. Manufacturer: made in Russia by an unknown company. Dating: bought in 2014. |

| 8 | Hollow split pin

with inside a firm, bended spring that adjust pin diameter when the

plug is pressed in a contact tube. Manufacturer: Voigt-Haeffner, Frankfurt a.M., Germany. Dating 1930s. |

| 9 | Pin

with a raised metal strip (red arrow). The strip is flexible and can be

pushed in fully. The effective pin diameter varies between 4.0 and 4.8

mm. Manufacturer:

GEMA, Berlin,

Germany. Dating: 1930s. |

| 10 | Plug

pin having in essence the shape of a (full-) split pin or cotter pin.

The ends of the two

parallel tines have sufficient flexibility to make stable contact with a socket tube.

The eyelet is functioning as wire connector. The plug cap (not shown) has to be closed fully to fasten wires firmly. Manufacturer: Clix, trade name of British Mechanical Productions, London, England. Dating: 1950s - '60s. |

| Examples of socket contact clip designs |

| 11 | 12 | 13 | 14 | 15 |

|

|

|

|

|

| 11 | Socket

contact designed by MK Electric in 1933 can be regarded as a first step

from tube to clip contact. Top of contact has splayed out jaws,

facilitating plug pin entry. The red annulus limits the widening of

socket entry, The spring ring below the annulus presses plug pin and

contact halves together. Manufacturer: MK Electric, Edmonton, Middlesex, England. |

| 12 | Compared to no 11 a next step towards clip contact. The main features are similar to the MK socket contact. Manufacturer: Feller AG, Horgen (ZH), Switzerland. Dating: 1960s. |

| 13 | Simple but effective type of clip consisting of two crossed parts kept together by the wire connector. Dating: 1960s(?). Manufacturer: Presto-Vedder, Altena, Westfalen, Germany. Crossed clips have been used by several more manufacturers. |

| 14 | Socket

contact comparable to no. 13 but clips are a single, not crossed unit.

Pin contact zone is kept together by a strong spring. Manufacturer: NIKO, Sint-Niklaas, Belgium; also used by other manufacturers. Dating: 1970s - '80s. |

| 15 | Nowadays most common type of socket contact. Clips are boxed up which limits the degree of widening out. Various manufacturers have designed similar variants. Example shown has been made by Merten GmbH, Gummersbach, Germany. Dating: from 2000s. |

| Straight blade plugs and matching sockets contacts (1) |

| 16 | 17 | 18 | 19 | |

|

|

|

|

|

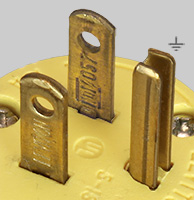

| 16 - 18 |

Standard US earthed NEMA 5-15 plug (no. 16) and two examples of sockets (17, 18). Japan uses similar plugs and sockets. Manufacturers: Leviton Manufacturing Company, Manhattan, USA (16, 17) and National (Panasonic), Osaka, Japan (18). |

| 19 | Uncommon type of standard not-earthed NEMA 1-15 plug. Straight blades have a flexible spring to enhance plug - socket contact. Image is based on a picture taken by Scot Kienzlen. The plug is attached to the appliance cord of a Lionel Electric trains transformer (type 1035; late 1940s). Manufacturer:name: Sta-Tite Manufacturing Company in Kansas City, Missouri, USA. The blade spring is mentioned in a 1948 Sta-Tite advertisement. Blade springs are identical to a patented electrical plug design by Emile P. Brus (Kansas City, Mo). US Patent Office. Patent request was filed on 30 July 1941. Patent US2337735A was granted on 28 December 1943. Similar blade springs are mentioned also in patent US2495206A, filed on15 May 1945 and granted on 1 January 1950. Sta-Tite electrical plugs are no longer produced, but the Sta-tide trademark is still used for specific fastening systems. |

| Straight blade plugs and matching sockets contacts (2) |

| 20 | 21 | 22 | 23 |

|

|

|

|

| 20, 21 |

Classic (no. 20) and modern (21) Australasian straight blade plugs. From 2015 pin sleeves are compulsory. Manufacturer: Elmaco Industries, Melbourne, Australia (20) and Elto Electrical Accessories, Auckland, New Zealand. |

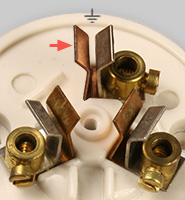

| 22 | Most common Australasian straight blade socket. Either both clip contacts are flexible, or only the "outer" clip (red arrow). Manufacturer: PDL Industries, Christchurch, New Zealand. |

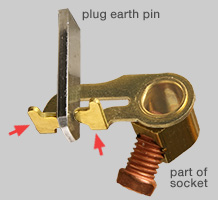

| 23 | A very different type of contact clips (red arrows) have been used on some sockets made by HPM

Industries,

Sydney, Australia. The socket has such clips for each of the three

straight blades, but for clarity only the earth pin connection is shown. |

| Plugs with rectangular pins and matching socket contacts |

| 24 | 25 | 26 | 27 | |

|

|

|

|

| 24, 25 |

BS

1363 plugs and sockets were introduced in Great Britain in 1947. Safety

shutters have always been obligatory; insulating sleeves from 1984.

Socket contacts has a shape comparable to image no. 22, but are necessarily

wider. Occasionally a rectangular brace was used to control the

distance between clip halves. Manufacturers: Volex (brand name used by Ward and Goldstone), Basingstoke, England (plug) and MK Electric Edmonton, Middlesex, England (socket). |

| 26, 27 |

Swiss

T23 16A - 250V plug and socket - introduced 1998 - have square pins, to

prevent the use of a 10A round pin socket for a 16A appliance. Sockets

and connector plugs (shown) have slightly conical contacts (see T23

clip). Manufacturers: Steffen AG, Würenlos (AG), Switzerland (plug) and Tschudin & Heid AG, Waldenburg (BL) Switzerland (connector). |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |