|

Appliance Connectors Classic models, part 1 |

overview |

| The museum collection of classic appliance

connectors is displayed on three pages. Part 1 shows plugs made of

ebonite, porcelain, serpentinite or steatite. Many early makers of domestic appliances in continental Europe were situated in Germany, therefore most connectors shown are of German origin. Details of manufacturers are given on a separate page. Nearly all items on this page have been donated by Reiner Hahn {RH}, who has provided also a lot of information about their origin and use. |

| Porcelain A white ceramic. It is an excellent insulator against heat and electrical tension that can be shaped in each desirable form. Porcelain has been used for plugs or critical parts of plugs for about a century. Steatite (soapstone) A technical ceramic. Like porcelain, grinded soapstone can be molded in forms and glazed in any colour. Dielectric and thermal properties are comparable to porcelain, but processing is easier and cheaper. From the 1920s steatite was much more often used for plugs than porcelain. The body colour of steatite is light beige, while porcelain is white (see image no. 8). |

Ebonite Hard, black vulcanized natural rubber. A relative high sulfer content and prolonged times of vulcanizing results in a solid product. Around 1900 it became the first choice material for - at that time - small series of plugs. They were hand made out of rods or plates of ebonite. In the 1920s ebonite was superseded by Bakelite that allowed production of large quantities of complex shapes. Serpentinite A greenish, brownish, or spotted mineral found in serpentinite rocks. Mostly used as decorative stone, but occasionally also used to make plugs (see no. 2). |

| Single pin

plugs Single pin plugs were versatile, because they were not restricted to equipment with one particular pin spacing. An advantage when pin spacing was not standardized. However, there could be a safety problem when only the line (AC) or + (DC) plug was connected. If the wall plug is already connected, the still open second contact pin on the appliance stands under tension too. Nevertheless single pin plugs had been in use in many countries until the 1930s. For replacement of broken or lost plugs they were even sold until the 1950s. |

|

|

|

|

| 1 | Flex cord with black

glazed steatite wall plug and connectors, rated at 6A-250V. Diameter of

plug pins and connector contacts: 4 mm. The wall plug - and likely also

the connector - have been made by Voigt & Haeffner AG, Frankfurt.

The inset shows their logo. Mid 1920s. {RH} |

| 2 | Pair

of German made serpentinite connectors. Inner diameter of contacts: 4.3

mm. Name of

the manufacturer is unknown.

Serpentinite is, among others, found in

the German Erzgebirge. In the region green and brown (bronzite)

serpentinite

has been used for plugs. All serpentinite plugs were handcrafted in

Zöblitz, which is still today the centre if serpentinite

processing. Serpentinite plugs have been made from

late 1980s until early 1920. {RH} |

| 3 | Porcelain

6A-250V plug and a black and white pair of steatite connectors. The wall plug has a Felmas trademark that was

used by Gustav Schortmann &

Sohn, Leipzig. Inner

diameter of contacts: 6.1 mm. Different coloured connector plugs are

either an aesthetic touch, or is related to + and - pole in a DC

network. The shape of the wall plug points to a 1920s flex

cord. {RH} |

| 4 | Ebonite pair of

appliance connectors. Inner

diameter of contacts: 6.2 mm.

Neither the connectors nor the wall plug have marks that could be

helpful to trace the name of the manufacturer. Ebonite has been used

from late 1890s until mid 1920s {RH} |

5 Appliance

cord with steatite connectors and matching porcelain wall

plug.

Inner diameter of contacts: 6.2 mm.

The

6A-250V plug

carries

the name Graetzor. The Ehrich & Graetz company in Berlin made in the 1920s and '30s among others a range of electric appliances under the name Graetzor. It is very likely that the company ordered plugs with the name Graezor from an independent manufacturer of installation materials. {RH} Right: Joy at home by GRAETZOR electric toaster and coffeemaker, according to a German 1931 advertisement. |

|

|

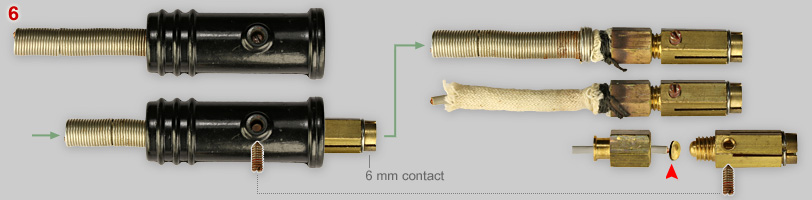

| 6 |

Most single pin connectors have a simple

system to attach a wire to the brass contact. One small bolt is used to

fix the wire and to keep the contact at the correct position inside the

insulating housing. A pair of appliance connectors donated by Wieger Nieuwenhout {WR} has a much more complicated system to connect a wire. The images from top left to bottom right show the various components of the connector. The red arrow points to a small concave disk. The wire is soldered to this 5.4 mm disk. This complex system offers a simple method to produce connectors with either 6 mm for 4 mm contacts. Possibly it could have been done by the end-user, without the necessity to rewire the plug. The plugs do not have any indication about the manufacturer. |

| Plugs with

two contacts For safety reasons already around 1910 some appliance makers developed connectors with both contacts in one casing. In the early 1920s an agreement could be reached on a standard for appliance couplers. Details about the DIN VDE 4990 standard are given below. From the second half of the 1920s single pin connecting was no longer allowed for new appliances. For traveling appliances with adjustable voltage single pin plugs were used even until the first half of the 1930s. |

|

|

|

|

|

|

| 7 | Porcelain

connector and matching wall plug of unknown origin (presumably German),

rated at 6A-250V.

Probably early 1930. Similar models have been made in the DDR (former

German Democratic Republic until the late 1950s. {RH} |

| 8 | Inside views of

connectors 7 (left) and 9 (right) shows the difference in colour

between porcelain (white) and steatite (greyish beige). The outside of

both

porcelain and steatite plugs is glazed. It gives the steatite plug

a porcelain look. |

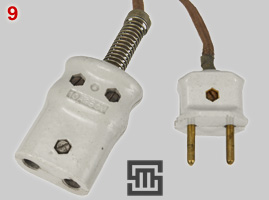

| 9 | Steatite connector and matching plug, made by Steatit-Magnesia AG in Teltow near Berlin. They used a logo with a rectangular S and M. Usual rating of 6A-250V. Second half of 1920s. {RH} |

| 10 | Steatite

connector

with metal cover plate. A sheet of mica underneath the plate protects

against contact with wires. Mica is not only a good insulator but also

withstands temperatures up to 900 ºC. The connector came with the

Therma

iron shown on the introductory page. Although made by the Swiss

company Thema (founded in 1907) the German standard of 19 mm spacing

and 6 mm contacts is used. Probably a mid or late 1920s model.

{YG} |

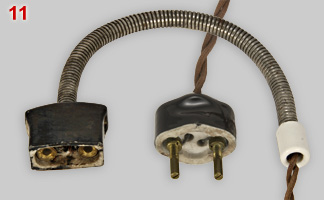

| 11 | A very early appliance cord (about 1910) especially made for flat irons. Plugs made from Steatite. Connector has a remarkably long (24 cm) flexible metal tube to prevent contact between cord and hot iron. No indications about the manufacturer, but surely of German origin. {RH} |

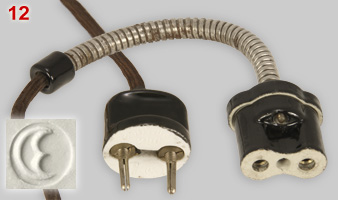

| 12 | Flex cord with steatite connector and 14 cm long flexible tube, probably made by Bayerische Elektrozubehör in Lauf bei Nürnberg (better known as ABL = Alfred Büttner, Lauf). The 6A-250V, porcelain wall plug has been made by Carl Ernst, Fabrik elektrotechnischer Steckkontakte in Berlin. The company, that had an attractive moon-like logo, didn't survived the 1929-'32 depression years. The flex cord has been made around 1925. {RH} |

|

|

| 13 | Connector with a nickel-plated casing to protect the steatite from breaking. It carries the trademark Protos, that was used during the second half of the 1920s and '30s by Siemens-Schuckertwerke in Berlin for a range of domestic appliances. The disassembled connector shows that only the tip is black glazed and the connector is not earthed, although the metal case may suggest otherwise. {RH} |

| 14 | Early

1950s porcelain

connector, rated at 10A-250V. The connector consists of a one-piece

porcelain housing with a small hole to cool the connector. Wires can be

fastened with screws that are accessible on the sides (green arrows). A clockwise rotating black ring with thread secures the cord, a feature designed by Richard Demmler. The figure left has been taken from the 1948 patent (a: porcelain body; c: ring with thread b). Brand name: Ridem, which was used by the company of Richard Demmler's Wwe (=widow) in Blechhammer, Thüringen. {RH} |

|

DIN VDE 4990 standard

Olymp iron with DIN 49491 appliance inlet.

DIN 49491 has replaced DIN VDE 4990. Both standards are essentially

identical.

Next page shows DIN 49491 plugs. |

> | A Commission

of the German Association of Electrical Engineers (VDE =

Verband Deutscher Elektrotechniker) started to develop a standard for

single case connectors in 1912. But a

comprehensive agreement on appliance couplers could be reached not earlier than 1920 because of WW I and different interests

of the producers. Characteristics of the DIN VDE 9490 standard were: (i) 19 mm** appliance pin spacing; 6.0 mm pin diameter (max. 6A-250V). (ii) Metal case to shield pins and providing the possibility to ground the equipment. (iii) Flex cords must have a flat connector with rounded ends and contacts for both pins. The connector may have earth clips. The image left shows an iron with an appliance inlet comparable to DIN VDE 9490. The standard became legal status in the second half of the 1920s. From January 1st, 1928 appliance couplers must have a VDE certification mark. The very successful system was soon taken over by many European appliance makers. For special purposes and replacements DIN 94941 plugs are still made, among others by Kalkhoff GmbH and Kopp GmbH (see list of German manufacturers). ** 19 mm spacing became the standard pin spacing for nearly all types of domestic plugs throughout continental Europe. 19 mm equals ¾ inch. For industrial purposes the inch has been used in many European countries for a long period of time. |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |