|

Appliance Connectors Classic models, part 2 |

overview |

| Part

2 of the collection of classic

appliance

connectors is devoted to Bakelite plugs made in Germany. Details of

manufacturers are given on a separate page.

Bakelite plug

production started in the early 1920s and was used for almost half a

century.

It was gradually replaced by other plastics in the 1960s. Information about molding marks has been given by Reiner Hahn. |

| Bakelite Bakelite was developed by Leo Baekeland in 1907 and patented in 1909. It is a phenol formaldehyde resin that can molded to produce large quantities of identical units. Although customized molds and molding presses were expensive, Bakelite became the preferred material for plugs as sales of electrical appliances increased dramatically from the early 1920s. Bakelite is an excellent insulator and is resistant to heat, but it may swell under prolonged humid conditions. Phenolic resins have to be reinforced with a filling agent. Sawdust was most commonly used in plugs. |

Molding marks The German Technical Association of Manufacturers of Standardized Molded and Compression Molded Materials introduced in 1924 an industry standard for Bakelite and comparable resins. Molding marks were issued by MPAD, the Staatliche Materialprüfungsamt zu Berlin-Dahlem (State Materials Testing Institute in Berlin-Dahlem). Molding marks have codes that identifies the press work and the pressed material. Images 4 and 8 shows examples. The former German Democratic Republic (DDR) used comparable DAMW marks (Deutsche Amt für Material- und Warenprüfung). Details are given at the page on the MPAD and DAMW marks. |

|

|

|

|

|

|

|

|

| Unless stated otherwise, for each of the

appliance connectors shown on this page applies: (i) rating of 10A - 250V, and (ii) contacts are designed for 6 mm pins, with a spacing of 19 mm. Connector nos. 1, 3, 5, 7, 9 - 22 and 30 comply with the old 6A DIN VDE 4990 (see part 1 page) or newer 10A DIN 49491 standard. |

|

| 1, 2 |

Early

Bakelite connector, made around 1925 or earlier. Note the solid

Bakelite cast. Later Bakelite casts were hollow (see image nos 3, 5

and 7). The outside has been painted dark brown to give it a more

decent

look. Other connectors with a solid Bakelite cast are nos. 13 and

19/20. Connector no. 1 has no company name or logo and no VDE or MPAD

mark, but it must have been made in Germany given the abbreviation

D.R.P. (Deutsches Reichspatent = German state patent). {RH} |

| 2, 3 |

1950s

connector, made by Leopold Kostal in Lüdenscheid (Westfalen). The

concept is essentially identical to no. 1, but through the years

connectors have grown in length. A hollow cast saves material and

together with a hole in the center of the

connector helps to cool down the plug, an essential feature if the

connector was used to power an iron, kettle or toaster. {RH} |

| 4 |

MPAD

molding mark of connector no. 3. The number above the M indicates the

press work. The testing institute has given no. 72 to Ludwig Kostal.

The other number refers to the pressing material. 31 = phenolic resin,

reinforced with sawdust filler (Bakelite). This material was also

indicated as Type 1 or S. Note that MPAD testing and certification was not mandatory, which may explain why connector no. 1 has no molding mark. |

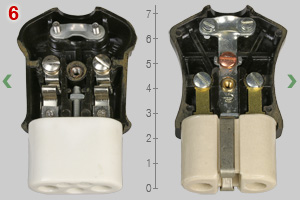

| 5, 6 |

1960s or

'70s connector with trademark Krania, made by VEB Elektroinstallation

Kranichfeld in Kranichfeld, Thüringen (former DDR). Connectors 5 and 7

are examples of models that have porcelain tips, giving a better

protection to heat. Although Bakelite is reasonably heat resistant,

fully Bakelite connectors used in irons suffered from degradation

and were more liable to break. |

| 6, 7 |

1970s connector with earth clips, made by von der Horst

(VDH) in

Lüdenscheid (Sauerland). Earth clips make contact with a metal case

around the

the appliance inlet pins, see

inset. {WN} |

| 8 | Top:

DAMW molding mark of connector no. 5. N25 = VEB Elektroinstallation Kranichfeld. Bottom: MPAD molding mark of connector no. 3. H7 = von der Horst, Lüdenscheid Both marks: 31 and 1 31 = phenolic resin, reinforced with sawdust filler (Bakelite). |

|

|

|

|

|

|

|

| 9 | Connector

probably

made by the Lüdenscheider Metallwerk AG, Busch-Jaeger. The connector

doesn't have any marks, but the wall plug that have the same look, has

Bush-Jaeger marks. The textile

structure was a feature of a luxury series. {RH} |

| 10 | Felmas connector no.

2820. The trademark Felmas* was used by

Gustav Schortmann & Sohn in Leipzig. Schortmann did not had his own

press work. The MPAD molding mark tells that the Bakelite parts came

from Bisterfeld und Stolting in Radevormwald (Rheinland). To improve

heat resistance Bakelite is reinforced with asbest type 1.

The connector is mentioned in a 1935 Felmas brochure. It states that

plug no. 2820 - the model shown here - can resist 250 degrees. {RH} *Felmas = Fabrik Elektrotechnischer Spezial-artikel. Felmas was in the 1930s one of the German market leaders for plugs and appliance connectors. After WW II Leipzig was situated in the Soviet occupation zone. Large parts of the East German industry were claimed by the Soviet Union for reparations. Among others Schortmann's company was badly hit. |

| 11 | Not earthed

appliance

connector. The metal case is for protection of the fully Bakelite

housing

only (see right image). Dating: probably mid 1920s. The

manufacturer is unknown; connector has no company logo or molding

mark.

{WN} |

| 12 | Two connectors made by Richard Hirschmann, Fabrik für Radioteile in Esslingen (Neckar). Left: non-earthed type with a luxury look comparable to connector no. 9. Right: earthed type. Both models have a relative large steatite part to protect the connector against heat. Probably 1930s models. {RH} |

| 13 | Earthed

connector made by Bayerische Elektrozubehör in Lauf bei Nürnberg, a

still existing company probably better known as ABL (initials of Albert

Büttner founder of the company in Lauf). Their MPAD molding mark code

is 67. The connector doesn't have the typical dark brown Bakelite colour anymore, but the molding mark shows that the product complies with the phenol resin with sawdust (code S) criteria. Discolouring can be caused by relative low resin percentage (<40%), addition of ammonia and/or wear and tear. The connector might be a late 1920s model. {WN} |

| 14 | Connector

with earth clips made by Dr. Deisting & Co. GmbH, Spezialfabrik für

elektrotechnische Installations-Apparate und Isolierstoff-Presswerk in

Kierspe (Westfalen). Probably early 1930s. {RH} |

|

|

|

|

|

|

|

|

| 15 | Connector with earth clips, manufactured by Gustav Schortmann in Leipzig, using the Felmas trademark. It is shown on the same 1935 Felmas brochure as connector no. 10. Besides the shown model no. 8980 two other variants were offered: a non-earthed type, and an earthed connector with switch. {WN} |

| 16 |

Not earthed appliance

connector rated at 6A -250V. Plug has VDE quaity mark, abbreviation DRMG (see below),

Felmas logo and MPAD moding mark with code 70-S. Felmas didn't had a

Bakelite press sacility. Bakelite (code S) cast production was

contracted out to Bisterfeld und Stolting (70). Dating: 1930s. {MN} |

| 17 | Side entry connector probably made by Lohmann & Welschehold in Meinerzhagen (Westfalen). The connector has the inscription B.G.M. (see below), but no MPAD mark. Dating: Possibly 1960s. {WN} |

| 18 | Side entry

connector made by in the 1960s-'70s by Gebr. von der Horst,

Elektrotechnische

Fabrik in Lüdenscheid. The company used both the VDH logo (see image

no. 7) as well as the Vaudeha trademark. MPAD mark is shown in image no. 8. |

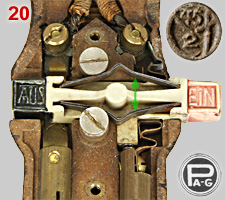

| 19, 20 |

Not

earthed connector with single pole push switch. Only the connection to

the right contact (see image no. 20) can be interrupted. Connector

manufacturer is ABL (Bayerische Elektrozubehör, Lauf), but

Presswerk AG in Essen (MPAD code 45) was responsible for type 2 casts.

Type 2 refers to an undefined thermosetting resin with organic filling

material. The springs (green arrow) of the push type on/off mechanism results in a sudden displacement of the contact strip over a relative large distance (ca. 5 mm). Quick motion is needed to minimize arc formation, a phenomenon that is more prominent with direct current than alternating current. Tumbler switches (for example no. 22) can only be used safely with AC. Because of slower on/off movement and smaller contact displacement metal contact points will be burned by DC arc formation. {RH} |

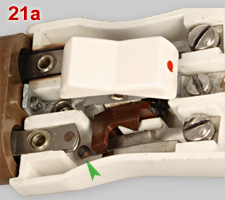

| 21, 21a |

Not

earthed connector with double pole tumbler push switch, made by Franz

Stauch,

Presswerk in Unterrodach (Oberfranken, Bavaria). According to the MPAD mark

the connector has type 31 = Bakelite cast, but its colours suggest the

use of a more modern plastic, using and older mold. Dating: 1970s-'80s. {WN} The green arrow points to the tip of a flexible metal blade. When the connector is switched to 'on' the blade moves upward and makes contact with the strip that is connected to the pin contact. Contact points and blade displacement are small, and up/down movement of the flexible blade is more gradual compared to a push switch. For reasons explained in the caption to connector no.18/19 the Stauch connector has the warning "Nur für Wechselstrom" (only for alternating current). |

| DRGM DBGM |

Plugs

15, 16 and 17 were protected by a German Gebrauchsmuster; a

patent-like property right. Novelty, inventive step and commercial

applicability are not examined in the registration process. This makes

utility model protection easier, quicker and cheaper to obtain than

patent protection. A Gebrauchsmuster protection is limited to 10 years;

a patent to 20 years. DRGM = Deutsches Reich Gebrauchsmuster (1891 - end WW II); DBGM or BGM = Deusches Bundes-Gebrauchsmuster; (from 1949 in the Federal Republic of Germany and from 1991 including former German Democratic Republic). |

|

|

|

|

|

|

|

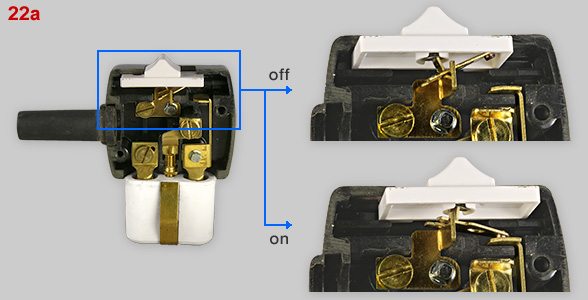

| 22, 22a |

Appliance

connector with earth contact and slide swich, rated at 10A - 250V.

Essentially a rocker switch, but operated by a slide knob rather than

tumbler (see no. 21). Manufacturer: Italian company Vimar.

{MC} |

| 23a-e | Electric travel iron (200W), made

in Germany by Neumärker; probably late 1950s. It can be used in

countries with a 220V, 150V or 110V network. Switching from one voltage to another is achieved by inserting the connector in a different orientation (see image nos. 23c, d and e). The iron is not earthed; the third pin of the iron (see image no. 23b) is necessary for making different contact configurations between the pins and the three slots of the steatite/Bakelite appliance connector (see inset; the fourth slot, indicated with x, is an empty hole). The connector - no. 1112 - has been made by ABL (Bayerische Elektrozubehör in Lauf). The wall plug has been made by Heinrich Kopp. Both have MPAD marks; connector: 67-31, and plug: W1-31. {FS} The image right has been taken from a 1937 ABL catalog (part of page 29). It shows a plug and appliance inlet (Geräte-Steckdose) similar to the above appliance coupler, devices that have been in production for at least 20 years. |

|

|

|

|

|

|

|

| 24, 25 |

Two

examples of 10A - 250V appliance connectors with a single sided earth

strip. Insets show the bended strip-end to ensure adequate earthe

contact. The use of these uncommon connectors is unknown. Both do not

have a manufacturer name, or MPAD mark. The sign "Made in Germany" may

indicate that both connectors have been made for export only. According to Mr. Jung, Spezielelectric in Ludwigsburg several companies have made 'asymetrical' connectors, among others: Stauch in Unterrodach, Kaiser in Hochstadt am Main and Karl Jung in Stuttgart (company information is given elsewhere). Dating: probably 1960s - '70s). {FSE} |

| 26 | Adapter to

convert a non-earthed appliance cord to a flex cord that can be used

for CEE 7/2 or 7/16 plugs that have 4.0 mm pins. Plugs with 4.8 mm pins

doesn't fit.

The adapter has been made by Willy Buschhaus, Fabrik für

elektrische Erzeugnisse in Lüdenscheid, Westfalen. It has a

DRPA mark (Deutsche Reich Patent angemelded = German patent

applied). A Bakelite adapter with DRPA is probably a 1930s model.

{RH} |

| 27 | 3-way

Schuko (CEE 7/4) multi-plug with appliance coupler inlet (DIN VDE

4991). Rating: 10A-250V. Manufacturer: Gebrüder Broghammer,

Uhrenbestandteile und Elektroapparate, in Schramberg (northeast of

Freiburg, Germany). Dating: 1950s. {RH} |

| 28 | A

'classic' DIN 49491 (now CEE type T155) appliance connector that is

still in production.

Kalthoff GmbH in Schalksmühle is one of few companies that still

offers

them for replacement and - in particular - for special purposes. The

model shown is

type 344/Si, rated at

16A-250V (Kalthoff

products). The housing is made of silopren, a two-component liquid silicone rubber for injection molding processes. It can withstand 200 ºC and for a short time up to 300 ºC. {RH} |

|

|

|

|

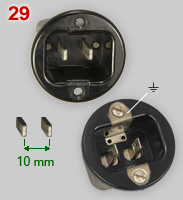

| 29, 30 | Inlets

(29) and plug (30) developed in the

1960s for non-household electrical

devices,

for example radios and office equipment, by Kautt

& Bux, Spezialfabrik für Kollektoren und Geräteschalter in

Vaihingen (Stuttgart). Rating: 6A - 250V; pin spacing: 10 mm. These appliance connectors and machting inlets can be regarded as precursors of the woldwide accepted ICE 60320 standard for appliance couplers. It is interesting to notice the use of side clips for earth contact. A system that is derived from DIN VDE 4990 appliance connectors shown above. |

| note 1 | he Czech company Elektro Praga still

offers appliance

connectors and inlets that are essentially identical to nos 29 and 30. A smaller 2.5A version is in production too. See image nos 15-17 on the Czech page. |

| note 2 |

Appliance

connector no. 30 is still available for replacing missing or

damaged plugs; see note 1. They for sale also by Wittner Cinetec, see Kaltgerätekupplung,

alte Version, in category Ersatzteile Divers. Information given by Evert

Liewes in 2019. |

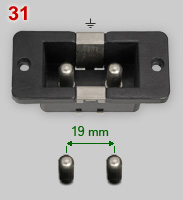

| 31 | Appliance

inlet with 6 mm pins, spaced at 19 mm suitable for DIN VDE 9409

and DIN 94941 earthed and not earthed appliance plugs (see nos. 1,

3, 5, 7 and 9 - 22). {WN} The manufacturer is unknown; the inlet has no logo, MPAD or certification marks. Among others the Dutch company Philips has used these so-called "Giant pin European mains inlet sockets" in power supplies and other electrical devices in the 1960s (information given by Evert Liewes). |

| 32 | Inlet for Schuko connector plugs. Rating: 10A (DC) / 15A (AC) - 250V. Both surface mount and flush type (shown) existed. Giving its size they were probably intended for (light) industrial purposes, rather than domestic appliances. MPAD code: 67 - 131 31. Manufacturer: ABL (Bayerische Elektrozubehör, Lauf bei Nürnberg). Dating: 1950s - '60s. {RH} |