|

Uncommon plugs / sockets Australia and New Zealand |

AS/NZS |

other specials |

|

Uncommon plugs / sockets Australia and New Zealand |

AS/NZS |

other specials |

|

A variety of plug / socket

configurations can be found in Australia and New Zealand. Most of them

are meant for special applications and some are rarely found in homes. First row: Standard 10A model with and without earth pin (plug shown on appliance connector page). Derived configurations for special purposes are shown in images 1 - 8 below. Second row: Configurations for 15 - 32A. Plugs and sockets are shown on the heavy duty page. Moreover, heavy duty three-phase plugs with various round pin configurations exist, but are not in the museum collection. Third row: Configurations mainly or exclusively meant for low(er) voltage circuits*. See images 9 - 16 below. Fourth row: Clipsal series of clock point plugs / sockets. See images 17 - 24 below. * parallel flat blade and 110V plugs are rarely used in Australia, possibly only in areas that are not linked to the national 230V - 50Hz power grid. For example mining companies operating in remote areas and/or using North American equipment. |

|

|

|

|

|

|

|

|

| 1, 2 | Plug and cord extension socket with standard pin / slot

layout with

transparent housing, rated at 10A-250V. Transparent plugs and sockets

make it easy to check internal connections. Recommended wiring:

1.5 mm2 extra heavy duty 3-core flexible cord. The given

rating and conductor size (10A and 1.5 mm2) allows a maximum

cord length of 35 meter. Manufacturer: Clipsal, Australia Pty Ltd. Cat. nos. 439SXHD-TR (plug) and 438XHD-TR (socket). {PT} S = safe, partly insulated power pins; XHD = extra heavy duty; TR - transparent. Plugs and extension cord sockets used in construction work must be of the non-rewirable (moulded) type or a transparent (clear) type. This requirement relates to equipment used in construction work and does not extend to electrical equipment used in other working environments – except the health industry sector, where the use of transparent plugs is required for new equipment, if rewirable (refer Australian Standard, AS/NZS 3200.1). |

| 3, 4 | Clipsal offers two variants of flexible plugs. Image no. 3 shows model 492, recommended for 0.75 mm2 or 1.0 mm2, 2- or 3-core circular cord. Model 492Y (image no. 4) is recommended for 0.75 mm2 two core figure 8 cable, or 0.75 mm2 2-core flat flexible cord. {PT} |

| 5, 6 | 10A socket (no. 5) and matching plug (no. 6) with a a round earth pin. It can specifically be used for controlled circuits, usually in commercial buildings. Manufacturer: HPM (part of Legrand group). |

| 7, 8 | 4 pin socket

with looping terminal

(two slots for active pins: A and an additional A2). Rating: 10A-250V.

The model shown is

meant for surface mounting. Image no. 8 shows the corresponding 4 pin

plug. Manufacturer: HPM. The extra terminal allows you to use the plug top as a switch when you plug it in. ACTIVE (A) goes up to the appliance, then through an overload cut out device. From that it comes back down to ACTIVE 2 and then to a relay or warning light on a panel or on the wall via the permanent wiring. The explanation was kindly provided by Chris Rickards, New Plymouth, New Zealand. |

|

|

|

|

|

|

|

|

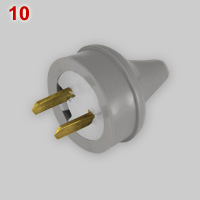

| 9, 10 | Non-polarised, parallel flat

blade socket and plug. The plug is essentially identical to NEMA 1-15P,

but not

polarized because the two blades have the same width. Manufacturer:

Clipsal, Australia; respectively cat. nos. 405 and 492Y. Plug rating is restricted to 7.5A-250V because of the type of cord that can be used with plug model 492Y. A model 492 that can be wired with 1.0 mm2 circular cord exists also, and is rated at 10A. The socket is rated at 10A-250V. {PT} |

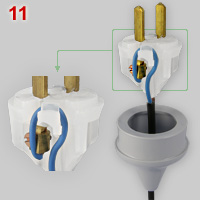

| 11, 12 | Both plugs have a unique system to fix

cords. After connecting wires to

pin terminals, the wires have to be wrapped under cord grip hooks (see

no. 7). Finally the white plastic inner part has to be pushed into the

flexible grey housing (no. 8). The anchoring system with cord grip hooks is available for all flexible models of two- and three-pin 10A plugs. {PT} |

| 13, 14 | Socket and plug rated at 10A - 110V. Manufacturer: Clipsal; cat.nos. 415/110 (socket) and 439/110 (plug). {PT} |

| 15, 16 | Polarised 2-pin Extra Low Voltage socket

and plug, rated at 15A - 32V. ELV plugs are used on farms which have

their own

generator/battery supply. Extra Low Voltage means: not exceeding 50V AC

or 120V ripple-free DC. Manufacturer: Clipsal; cat. nos. 405/32 (socket) and 492/32 (plug). {PT} AS/NZS 3000:2000 states among others that plugs and sockets for ELV shall comply with the following*: (a) Plugs shall not be able to enter socket-outlets of other voltage systems. (b) Socket-outlets shall not accept plugs of other voltage systems. (c) Socket-outlets shall not have a contact for a protective earthing conductor. Where the ELV supply is referenced to Earth, the radial pin should be the Earth pin. Outside of these situations it is recommended to consider the radial pin as Neutral and the remaining pin as Active, although these connections can be reversed**. Sources: * ExplorOZ Forum (Australia). |

| I am grateful to Peter B. Taylor {PT} for

not

only sending material but also

providing essential information about Australian plugs and sockets. |

| Clock plugs and sockets |

|

|

|

|

| ↑ | ↑ | ↑ | |

|

|

|

|

| 17 | Clipsal, Australia has developed a series

of

three clock point plugs and sockets to provide semi permanent

connection of electric clocks. The sockets (10.5 x 5.8 cm) flush

with the wall surface. Plugs fit down into the recessed socket. Plug

and socket are out of sight when using a sufficiently large

clock. {AR} |

| 18, 20, 21 |

Unswitched, recessed socket (image no. 18; Clipsal cat. no. 408-3) and plug (image nos. 21 and 22; cat. no. 409-3) rated at 5A-250V, meant for stand alone clocks. However, they can also be used for other low drain appliances. {AR} |

| 19, 23 | Four pin clock point socket and plug (cat. nos. 408-4 and 409-4) for synchronous slave clocks. Synchronous wired clocks contain a motor and correction armature. Each clock varying from system time - for example because of a power failure - can be individually and automatically corrected by synchronisation with a time control centre. The fourth - CORR - pin is used for pulses to correct the clock. {AR} |

| 20, 24 | Socket

and plug (cat. nos. 408-3A and 409-3A) for 32 Volt DC impulse slave

clocks*. Also this type of clock is individually checked for agreement

with a time control centre. * The indicated rating for this model in the 2005 Clipsal catalogue is 5A - 250V AC. {AR} |

Another type of clock plug and socket, designed for the UK market, is made by MK Electric (click here for details). |

|

|

25, 26 For safety reasons it is compulsory in Australia and New Zealand that a direct contact with metal parts of a socket is impossible. This means that fixing screws have to be out of reach or insulated. There are several methods to achieve this. (1) fixing screws are hidden behind a press-on wall plate; see image no. 25. Nowadays this is the most common method. (2) fixing screws are recessed and covered by a plastic cap; see image no. 26a,b. (3) fixing screws have an insulated head; see image 26c. This method is no longer applied, but can be found on older sockets, as shown on the page about classic models. |

AS/NZS

D i g i t a l M u s e u m o f P l u g s a n d S o c k e t s

specials