|

Locking Plugs overview of types in museum |

info page |

| Locking plugs prevent accidental

disconnection that may have unwanted and possibly dangerous

consequences because

lighting fails or equipment comes to an untimely or unsafe stop. Various mechanisms have been designed to secure special plugs in combination with adapted sockets. An overview of classic and modern locking plugs in the museum collection is given below. → Click on

an

image for additional information and matching socket.

|

|

|

|

|

| 1 | The US

National Electrical Manufacturers Association (NEMA) has defined a

large number of amperage, voltage and grounding specific locking plug

configurations. Pins of twist lock plugs are rounded and have a flange

to lock the plug

(see green arrow). |

| 2 | Danish twist lock

plug for

ceiling sockets, designed to connect lamps. Locking mechanism is

comparable to US plugs (see no. 1). |

| 3 | Japanese locking

sockets use the holes in flat blades to fix a plug after rotation. See

also nos 17 and 18. |

| 4 | British EPOS

(Electric Point of Sale) plug. After insertion in a matching socket the

plug is locked by rotating 90°. |

|

|

|

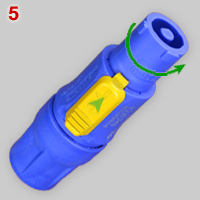

| 5 | Neutrik

PowerCON plug. After insertion in a PowerCON socket and 30° rotation,

the yellow clip locks the plug. |

| 6 | British bayonet cap

plug. Bayonet plugs were initially meant for lighting only, but

adapters for BS 372 2-pin plugs existed also. |

| 7 | Three-phase plug

with bayonet-type locking mechanism, made by the German company Kontakt

AG

in the 1930s. |

|

|

|

|

| 8 | Plug with a screwed,

restraining ring to secure the plug after inserting in a socket with

matching spiral thread. |

| 9 | Concentric plug with

locking mechanism similar to no. 8. The German Maehler & Kaege plug

dates back to the 1950s. |

| 10 | A cutout of the

earth pin (green arrow) enables the matching socket to secure the plug

with

a bar. Locking mechanism has been designed also by Maehler & Kaege.

Dating: early 1930s. |

| 11 | British plug with

slotted earth pin, made in

the 1950s by General Electric Company. Locking mechanism is comparable

to no. 10. |

|

|

|

|

| 12 | IEC

60329-C13

connector plug. When pushing the connector into an appliance inlet, the

metal plate (green arrow) glides easily around the inlet earth pin

but blocks attempts to retract the connector. |

| 13 | French DCL plug

(Dispositif de Connection Luminaire). A clip (green arrow) locks the

plug in a DCL lamp socket. |

| 14 | Wylex clock

connector. A long screw keeps socket and plug together. Dating: 1950s. |

| 15 | Plug

with hollow pins. The cavity is slightly conical. Pin tips can be

pushed away from each other by a (black) plastic bar; triangles (green

arrowheads) fix pins in the socket contact. |

|

|

|

| 16 | Plug is a standard Schuko model inserted into a socket with rotary switch. In switched on position, the knob of the switch locks the plug. It is essential that the plug has a collar (green arrowhead). Nearly all classic Schuko plugs had a collar. |

| 17 | Connector with mechanism to lock

CEE 7/4, -7/6, -7/7 and -7/17 plugs. Rotate connector collar to lock /

unlock

plug. |

| 18 | Adapter

plug with locking mechanism connected to tube around earth pin. Press

red button to unlock plug. Click image for details. |

| In the true sense of the word, plugs 19 - 22 are not

locking plugs. Straight blades of plugs 19 and 20 have holes. Matching

sockets have small balls that fit partially in the

holes. Balls help to keep plugs in position. Pins of plugs 21 and 22 show other types of plug fixation; see captions. |

|

|

|

|

| 19 | US 15A-125V non

grounding plug. Although not

compulsory, many US straight blades have

holes that help to fix plugs. See nos. 1 (US) and 3 (Japan) for genuine locking plugs. |

| 20 | Classic Danish plug

designed for lamp sockets. Image No. 2 shows a modern, locking

type Danish lamp plug. |

| 21 | Classic

Australian 10A plugs often had recesses at the top of each of the

blades (green arrows). Their function was comparable to holes

in straight blades (see nos 17 and 18). Already in 1904 Harvey Hubbell

patented plug blades with recesses and

matching outlet contacts with indentations adapted to engage blade

recesses (see images A, C and D on Origin of US plugs and sockets

page). Ultimately the Hubbell method of

fixing plugs has been outstripped by the "hole and ball" method shown

in image no. 17. The origin of Australian plugs is a 1915 design by George Knapp, working at Hubbell Inc. (see image E). Whether Australian sockets initially had contacts with indentations is not clear. None of the classic outlets in the museum collection have the provision. Modern Australian plugs have flat blades without recesses or holes. |

| 22 | Porcelain

round pin plug made in Germany in the 1910s. They often had

round pin tips, which helps to insert plugs into socket contacts. The

additional circular recess is either a decorative feature, or -

occasionaly - a provision to fix plugs. An example of the latter

function is

shown on Classic

Uncommon Plugs page (see Voigt & Haeffner socket no. 28). |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |