|

Technical improvements to enhance plug and socket safety |

general info |

| Looking

at the white porcelain socket below it will be clear that to nowadays

standards it is an unsafe model. Fortunately the socket dates back to

times that 110 Volt was the common domestic current. Touching a 110V

contact is dangerous, but usually not lethal. Touching exposed parts of

220-240V sockets, plugs or

appliance parts under tension may have far more dramatic consequences.

See Wikipedia entry 'Electrical

injury' for details. Through the years several technical improvements have been made to enhance safety of electro- technical accessories. Gradually they became mandatory in standards world wide. |

The web page focuses on technical

improvements related to domestic

single phase electricity. Three phase and heavy duty devices, meant for

industrial use, have to comply to additional safety rules. Below only one example shows a type of technical improvement, not necessarily being the earliest model. Companies in different countries may have developed improvements independent of each other, more or less at the same time. No attempt has been made to construct a kind of time line. Names of manufacturers are omitted. Meaningful improvements have been implemented by all competitive companies. |

| Classic sockets and plugs were often prone

to accidents |

| 1 |

2 | 3 |

|

|

|

| 1 | Porcelain socket with exposed contacts. Risk of electric

shock by touching with

finger or metal object. Improvement: safety shutters (see image 5). |

4

|

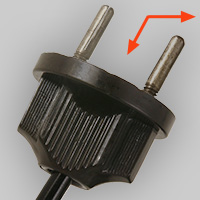

| 2 | Risk of electric shock by touching not fully inserted pins,

because pins are already connected to socket contact. Improvements:

recessed sockets (see image 6) and/or plugs with

insulating sleeves

(see images 8). |

|

| 3 | A plug pin of an appliance cord is connected to the line

(phase) socket contact, while the other pin is outside the

socket.

Touching the outside pin results in an electric shock. Improvement: larger socket (see image 7). |

|

| 4 | Risks

of electric shocks visualized in images 1, 2 and 3 apply to connector

plugs also. |

| Socket safety improvements |

| 5 | 6 | 7 | |

|

|

|

| 5 | Socket

with safety

shutters. Plug pins have to be pressed down simultaneously to rotate

shutters away. For 3-pin plugs it is often the earth pin that shift shutters away (see for example image 12). Earth contacts don't have a shutter. Several shutter systems exists; details are given on a separate page. |

|

| 6 | Recessed socket.

Shown is a Schuko socket with 18 mm deep recess (see also plug 11).

Sufficient safe depth depends on distance between top of socket

contacts and

surface of recess + depth of recess, in relation to plug pin length.

For example Schuko: distance to contacts 8 + 18 = 26 mm and length of

Schuko plugs is 18.5 mm. Touching pins under tension is not possible. |

|

| 7

note |

Socket with

sufficient large size to prevent insertion of a single plug pin, as

shown in image 3. Distance between center of socket contact and socket edge have to be at least 20 mm for plugs with 19 mm pin spacing. Possibility to insert a single pin still exists when using some adapter plugs. See image right >> |

| Plug safety improvements |

| 8 | 9 | 10 | |

|

|

|

|

| 8 | Insulating pin sleeves prevent an electric shock when touching a partially inserted plug. The percentage of a plug pin that is insulated differs between plug types, but is around 50% (+/- 10%). Earth pins never have sleeves (see plug nos 12 and 13). Line and neutral pins of plugs that are used in recessed sockets usually have no sleeves. The recess offer already sufficient protection. |

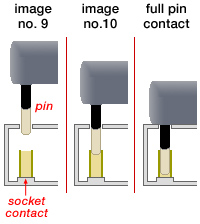

| 9 | Plug

is partially inserted, but pins doesn't touch socket contacts. See

schematic drawing right. No risks when touching metal parts of pins. |

| 10 | Plug

pins are just connected to socket contacts. Only insulated parts of

pins can be touched. To power an appliance the plug has to be pressed

fully down; see scheme. The space between socket cover and top of contact is sufficiently large for safety shutters (not drawn in scheme). |

| Protective Earth Connection |

| 11 | 12 | 13 | |

|

|

|

| info |

A

damaged wire insulation may allow charge to flow along an unintended

path,

for example the metal housing of an appliance. Touching the

appliance results in a serious electric shock that may cause a deadly

cardiac arrest. The chassis of appliances that have exposed metal parts must be connected to a separate earth conductor.* The protective earth conductor is the first connection when plugged in and the last to be broken when the plug is removed. |

Images 11-13 show examples that meet the requirement. A short circuit between phase and neutral, or phase and earth is likely to result in a high current that triggers the overcurrent protection device in the meter box or blows a fuse. Low leakage currents will be discontinued by a residual current device (see nos. 23 and 24). Sources and more information: Wikipedia (1), Wikipedia (2). |

| 11 | Schuko plug with two

earth clips. Earth clip makes contact first. Image 6 shows a Schuko

socket. |

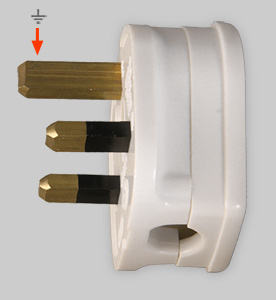

| 12 | British BS 1363

plug. Earth pin is 5 mm longer than line and neutral pins. Earth pin

pushes line and neutral shutters away and makes contact first. Note

that the cord exit is at the plug side, rather than plug top; see Cord

grip for explanation. |

| 13 | Swiss T12 domestic

plugs have three pins of equal length. Matching T13 socket earth

contact has a 5 mm advanced position compared to line and neutral

contacts which ensures that earth contact is made first. Besides Swiss also Danish domestic sockets have an advanced earth contact. |

| * note |

A protective earth connection is not required for double insulated electrical appliances that have a reinforced protective insulation in addition to basic insulation. |

|

A square within square is the symbol for double insulated (Class II} appliances. Plugs without protective earth pin can be used safely (for example plug no. 22). |

| Connection

between socket contact and plug pin |

| 14 | 15 | 16 | 17 | 18 | |

|

|

|

|

|

| 14 15 16 |

Initially

socket contacts were simple hollow tubes. Split pins (image 15) were used to ensure sufficient and stable plug pin contact. Using a knife or screw driver the distance between both pin halves could be adapted. However enlarging the split size resulted occasionally in breaking off a plug half (image 16, left arrow). Pressing the halves firmly together results in a too small pin diameter to make stable contact (right arrow). |

| 17, 18 | Modern

socket contacts have one or another type of flexible clips that ensures

stable pin contact and allows

the use of solid pins. Image 17 shows a contact type with a spring

keeping the clip tips together. Several more flexible clip

variants exist. Diameter of solid pins (image 18) depends on the plug rating; 4.0 mm for max. 10A, and 4.8 - 5.0 mm for 16A. |

| Cord grip |

| 19 | 20 | 21 | 22 |

|

|

|

|

| A sturdy wire connection and firm

plug cord grip are essential to prevent unattended disconnected wires. |

|

| 19, 20 |

Plugs that

have been used in the first decades of the previous century often

had a rather basic and reduced reliable method to attach wires to pins.

Many of these plugs did not had an additional cord grip. Unplugging by

grabbing the cord, rather than using the plug itself, is

asking for troubles. A

modern cord type has been used to illustrate the method to attach

wires.

|

| 21 | Inner part of plug

with robust

cord grip (red arrow). Nevertheless, grabbing cords is still unwise. |

| 22 | Molded

cord; a very different type of cord grip. Plug and cord are an

inseparable unity. Often used for appliance cords with any type

of wall plug and IEC 60320 connector plug. Image shows a CEE 7/16 mains

plug (Europlug). |

| cord exit |

Most

plugs have a plug top cord exit (see no. 19), but a side exit exists

also. It can be more convenient for wall sockets (cord is hanging

down), but it is also more safe. Unplugging by grabbing a side exit

cord

is quite ineffective. For this reason it is mandatory that British

domestic plugs (BS 1363) have a cord side exit (see no. 12). |

| Residual Current Device (RCD) /

Ground Fault Circuit Interrupter (GFCI) |

| 23 | 24 |

|

|

|

|

| RCD info |

RCDs

are designed to disconnect the circuit if there is a leakage current.

They operate by measuring the difference between current flowing

through the live (line) conductor and that returning through the

neutral conductor. If these do not sum to zero, there is a leakage of

current to somewhere else. Somewhere might be a person touching a live component of a socket, plug or appliance causing some of the current to take a different return path (body), instead of neutral conductor. RCDs detect small leakage currents (typically 5–30 mA) and |

disconnect the circuit sufficiently quick (<30

milliseconds) to prevent a serious electric shock. A small leakage current, such as through a person, can be a serious fault, but would probably not increase the total current enough to blow a fuse or activate an overload circuit breaker to isolate the circuit, and not fast enough to save a life. Source

and more information: Wikipedia

|

| 23 |

Example of

one of the RCDs on the mains switchboard of the plug and socket

collector's home (Netherlands). Additional, compulsory, overcurrent

protection

devices are not shown. RCDs are mandatory in an increasing number of countries worldwide. |

| 24 | Dual NEMA 5-15

socket with a GFCI. In the US and Canada the name Ground Fault Circuit

Interrupter (GFCI) is used rather than RCD. In the US and Canada local electrical codes requires that GFCIs* be used in all kitchens, bathrooms, garages and outdoors. * usually a NEMA 5-15 dual socket with build-in GFCI. For outdoor use GFCI in-line portable adapter cords exist. |

| ElectroStatic Discharge (ESD) |

| 25 | 26 |

|

|

|

|

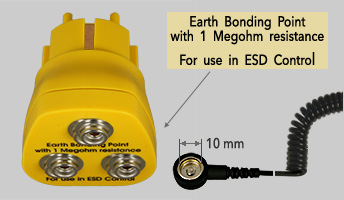

| ESD info |

Static

electricity is an imbalance of electric charges within or on the

surface of a material. The charge remains until it can move away by an

electric current or electrical discharge. In particular semiconductor devices are very sensitive to the presence of static electricity. Antistatic straps and mats connected to ESD earthing plugs are necessary in production processes to avoid damage by static electricity. |

Earth plugs are usually connected to strap or mat

through a coiled retractable cable and 1 megohm resistor, which allows

high-voltage charges to leak through but prevents a shock hazard when

working with low-voltage parts. |

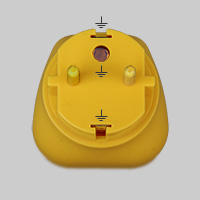

| 25 |

ESD earthing

plug with 1 megohm resistance end three 10 mm push button contacts.

Connection to antistatic strap of mat is made by a spiral cable. Other

end of cable (not shown) has either a 10 mm push button or crocodile

clip. |

| 26 | Design of the ESD earthing

plug is based on CEE 7/7 (Schuko hybrid plug), but only the earth

contacts are active, being two CEE 7/4 earth clips and a CEE 7/6

contact for 4,8 mm earth pin. |

The shown ESD plug doesn't have a manufacturer's name or logo. The spiral cable has a SG logo (see image). SG stands for Safe Guard. Probably a trade name used by the Chinese company Safety Working Tech in Shenzhen, Guangdong province. |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |