|

Classic continental European not earthed plugs and sockets, part 2 |

flat plugs |

| Besides two more sockets, part 2 shows

plugs that have a

round base (∅ 36 mm ± 1.5 mm), made of

porcelain, steatite or Bakelite. Part 1 shows

flat plugs. Unless stated otherwise plugs have the following features in common: 1. Pin diameter of 4 mm and pin spacing of 19 mm. Pin length is 19 mm ± 0.5 mm. 2. Rating, if indicated, of 6 Amp - 250 Volt. Bakelite plugs and sockets made in Germany often have a molding mark that identify the press work and the pressed material. Details are given at the page on MPAD and DAMW marks. |

|

|

|

|

|

|

|

| 1 | Porcelain

socket with grooves to guide plug pins to socket contact holes. Grooves

are an invention of Hanns Benkert, working at Siemens-Schuckertwerke AG

in

Berlin. German Reichspatentamt granted the patent application on 24

December 1938 (see

Depatisnet document DE000000669390A). Socket rating: 10A - 250V. Dating: 1950s {RH} Manufacturer is unknown, but the quality mark 1 (bottom left) points to a company in the German Democratic Republic (DDR). |

| 2 - 3 |

Example

of a very common type of surface mount Bakelite socket, rated at

10A-250V. Sockets

had (and still have) a shallow recess; diameter varies between 37 and

39 mm.

The combination of a recessed socket and round plug base gives a good

protection against touching pins under tension. The type of contacts

(images 3 and 4) is simple but effective and was used by several

manufacturers. Contacts are accessible for plugs

with 4.0 and 4.8 mm pins. Trademark Presto was used by Gebrüder Vedder, Fabrik elektrotechnischer Apparate in Schalksmühle (Westfalen, Germany). company, founded in 1904 is later renamed to Presto-Vedder and still exists. Dating: 1930s -1960s. {RH} |

| 5, 6 |

Socket

with four outlets, rated at 10A - 250V. Image no. 6 shows the steatite

body and efficient 'wiring'. Manufacturer: Erich Jaeger in Homburg vor

der Höhe (north of Frankfurt). Dating: 1950s. {WN} |

| 7 | Extension

cord socket with four outlets, rated at 10A - 250V. In older homes

there were usually a very limited number of wall sockets, consequently

extension cords with multiple outlet sockets were popular.

Manufacturer: Busch-Jaeger in Lüdenscheid. Dating 1960s.

{WN} |

|

|

|

|

|

|

|

|

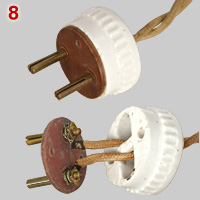

| 8 | Porcelain

plug with bottom plate made of insulating board. It was a 'classic'

model that has been produced for a log period in France and other

countries. Manufacturer is

unknown. Dating 1900s - 1930s. {RH} |

| 9 | Steatite plug. Fixation if wires correspond to a quite commonly used mechanism shown in more detail in image no. 18. Unknown brand; probably made in Germany in the late 1910s to 1920s. {RH} |

| 10 | More sophisticated steatite plug from Siemens-Schuckertwerke in Berlin (right logo). The steatite body was produced by Steatit-Magnesia, Dralowid Werk in Teltow bei Berlin (left logo), a company that was responsible for steatite parts of many plugs and sockets of various manufacturers. Dating: 1920s. {RH} |

| 11 | Two similar steatite plugs of unknown German origin. Apart from the use of black versus white glaze only the method to fix the upper and lower part of the steatite housing is essentially different. Bolds of the black plug are exposed and resembles plug nos. 9 and 10 shown on part 1 page. The bolds of the white plug are countersunk, a more safe design. Therefore the white plug might be a more advanced and/or luxurious model. {RH} |

| 12, 13 |

Compared

to Bakelite plugs (see below) it is more difficult to provide porcelain

plugs with an effective cord grip. However methods to prevent that

cords are fixed only at the pin

contacts have been developed. The plug made by Thega-Kontakt in

Berlin has holes on both sides, close to the cord exit. Image no. 13*

shows how a thread through these holes can be used for cord fixation.

{RH} * Image no. 13 is an edited version of a picture found on Ebay. Plug nos. 12 and 13 are not identical. |

| 14, 15 | Felmas*

plugs has developed a cord

fixation method comparable to images 12-13. Holes for

the thread are positioned in the basal part of the plug. Image no. 15

is a

top view of the Felmas plug. Holes at 3 and 9 o'clock are used by

electrical wires; holes at 12 an 6 o'clock are meant for the tread to

fix the cord. Plug nos. 12 and 14 probably date back to the

1920s. {RH} *Felmas = trademark of Gustav Schortmann & Sohn Fabrik Elektrotechnischer Spezial-artikel in Leipzig. In the 1930s it was one of German market leaders for plugs and appliance connectors, but after WW II the company hardly survived Soviet Union reparations. There have been made Felmas installation materials, but the successful prewar years were definitely over. |

|

|

|

|

|

|

| 16 | Siemens-Schuckert

plug type NSt 6/2 k, made from about 1910 until 1930. Plug consists of

a single block of an early synthetic pressed material, reinforced with

asbestos

fibers. Screws to attach wires to pins are accessible from outside but

cannot be touched when the plug has been put in a recessed socket. The

circular incision close to pin tips help to fix the pins in specially

adapted socket contacts; see 3-phase

socket no. 25.

The strongly build plugs were probably mostly used for commercial

equipment, rather

than domestic appliances. {RH} |

| 17 | Steatite plug made by Voigt & Haeffner in Frankfurt. Dating: 1920s. The plug is remarkable because of its pin design. Pins have inside a long, bended spring. The spring prevent that split pins remain pressed together after having been inserted in a relative narrow contact of a socket or connector. Squeezed pins were a common feature of plugs with split pins. {RH} |

note |

Image nos. 18 to 33 show Bakelite plugs that are made between late 1920s and mid 1960s, but used even longer. The museum collection has dozens of examples made by a large number of manufacturers. Most plugs are German made. Others are made in France (Legrand, l'Ébénoid), Belgium (Vynckier), Italy (A.A. & G Stucchi) and the Netherlands (Corodex, HAF). Find below a small selection of plugs that illustrates the diversity in shape and design. Attention is given to wire fixation and cord grips. |

| 18 | Basic

model with a relative small cast, without base plate. Made by Spelsberg

& Koring in Altroggenrahmede (Westfalen, Germany). Wire fixation:

comparable to image no. 20; no cord grip. Probably early 1930s.

{WN} Although the plug has no cord grip, there is still a possibility to secure a cord according to a method shown on a separate page. |

| 19, 20 | Basic

model with protective base plate. Pins have a screw thread to fix pins

in the Bakelite cast. The thread is also uses by a circular nut for

wire fixation, a method that was also frequently used on porcelain and

steatite plugs (see nos. 9 and 14). No cord grip. The example has been

made by Weisse & Co., Fabrik elektrotechnischer Artikel in

Gräfenthal (Thüringen). The production of such plugs started in the

1930s and may have lasted until the late 1940s. |

| 21 | Bakelite plug made by Felmas. Gustav Schortmann introduced in 1935 a method to fix the cord. It was - and still is - an unsafe habit to remove a plug by using the cord as a towline, which means that the contact between wires and pins have to withstand considerable towing forces. Felmas plug type 3003 has a large bold (green arrow) to fix the cord. In a Felmas leaflet it is claimed that the construction is "bombenfest" (i.e. extremely robust). {RH} |

|

|

|

|

|

|

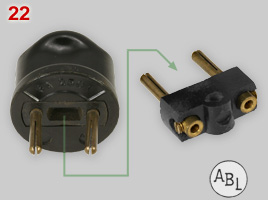

| 22 | Plug

made by Bayerische Elektrozubehör, founded by Albert Büttner in Lauf

bei Nürnberg (hence ABL) in the 1923s. The plug shows a rather unique

approach to facilitate wiring by simply detaching the Bakelite pin

holder. The plug doesn't have an effective cord grip. {WN} Note that 'Graetzor' porcelain appliance connector no. 5 has a similar detachable pin holder. It might be that an ABL patent has been used for the connector. |

| 23 | After unscrewing the base plate it is easy to wire this plug. It is one of the designs in the Protos series of Siemens-Schuckertwerke in Berlin. No cord grip. Dating: 1930s {WN} |

| 24 | Plug with cord side entry, made by Nostitz & Koch, Fabrik elektrotechnischer Apparate in Chemnitz (Sachsen). The cord side entry has a height of only 3.5 mm. A cord with a diameter of ca. 4 mm will be squeezed tightly between basal part and plug cap. Thinner cords have no grip and the use of thicker cords will result in a not fully closed plug. Dating: 1940s. {WN} |

| 25 | ABL plug with a

strong, metal cord grip.

A 1937 ABL catalog mentions the plug made of brown Bakelite to which

textile was added. This luxury model was more expensive than the

standard, black Bakelite model (90 versus 60 Mark per 100 plugs).

{FSE} |

| 26 | Plug made by Leopold Kostal in Lüdenscheid (Westfalen), characterized by an unusual type of pin fixation. Dating: 1950s-'60s. {WN} |

| 27 | The most 'modern' type in the series of Bakelite plugs. In contrast to each of the previous models this plug has solid pins with a diameter of 4.8 mm, rather than 4.0 mm partly split pins. Because of thicker pins, it is rated at 10A-250V and can be regarded as a direct precursor of CEE 7/2 plugs. The plug has been made in the 1960s by Erich Jaeger in Bad Homburg vor der Höhe. {WN} |

|

|

|

|

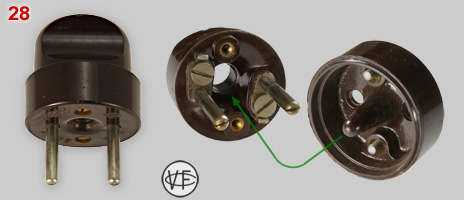

| 28 | 1930s plug made in Belgium by Vynckier Frères & Co. in Gent. It has an less usual type of cord grip. The basal part has a large Bakelite cone that presses the wires to the circular wall of the cord exit. The amount of pressure is controlled by the force that is applied to assemble both parts of the plug, A method that works good for separate wires with a diameter of 2.0 - 2.5 mm. {WN} |

| 29 | Plug and matching connector made by Wolff & Co. in Walsrode (north of Hanover). Cords can be fixed with large screw at the sides (green arrows). Compare with Felmas plug no. 21. The plug cord is protected by a flexible, 4 cm hollow spring, a feature commonly found on appliance connectors, but rare on ordinary plugs. Dating: second half of 1930s. {WN} |

| 30 | Large (cast length: 83 mm), watertight plug. The porcelain cord grip is flanked by a rubber seal and flat washer. Brand name: Stotz-Kontakt, Fabrik elektrotechnischer Spezialartikel, Mannhein (from 1939 Heidelberg; now part of ABB Busch Jaeger). The Bakelite cast has code 32-S, which means that it has been made by Preßstoffwerke H. Römmler in Spremberg (Brandenburg). {WN} |

| 31 | 6A plug and 10A

connector

made by Corodex, a no longer

existing Dutch press work that made

its own thermosetting plastics. The product range was very diverse.

Products were either made for other companies or marketed as Corodex.

The

shown models dates back to the late 1950s - early '60s.

{WN} |

|

|

|

|

|

|

|

|

| 32, 33 | 10A

plug with steatite body and Bakelite housing, made by the Norwegian

company Brødrene (=brothers) Braathen in Oslo. Image no. 33 shows the

simple, but high quality method of wire attachment to the solid brass,

5.0 mm pins. {RH} |

| 34 | Bakelite

plug with

two protective rubber bands (green arrows). The plug has solid 4.0 mm pins; in the 1930s an

uncommon feature. An advertisement for this "unbreakable" plug is shown

in the Elektrotechnische Zeitung, Vol. 53, no.10 (March 10, 1932). Manufacturer: Ernst

Rademacher, Fabrik technischer Leuchten (lighting products) in

Düsseldorf. The Bakelite cast has been made by Volkenrath & Co. in Schwenke. {WN} |

| 35 | 6A

plug made in Italy by VLM S.p.A.* The groove offers a remarkable good

grip to retract the plug. The unique, high quality, VLM plugs have been

used among others on (Italian) design table lamps in the 1970s. * Now a part of Relco Group in Buccinasco (province Milano). |

| 36 | Bakelite plug and cord molded in a protective rubber housing made by AEG (Allgemeine Elektricitäts-Gesellschaft in Berlin). The technique of making fully watertight appliance cords was an important improvement for equipment that was used under wet conditions. Both Siemens and AEG offered sealed appliance cords under the name Flexo. AEG has sold them at least up to the early 1950s. {RH} |

| 37 | Rubber

plug rated at 6A - 250V made by Gebrüder Merten in Gummersbach (GMG) in

the 1950s-'60s. The rubber housing, which consisted of matural rubber

(butyl-caouchouc), has been made by ERSO-Elektro GmbH & Co. in Bendorf. {RH} |

| 38 | Basic plug model, rates at 10A-250V. The zigzag course that wires have to follow takes tractive forces away from the pin screws.The plug doesn't have any certification marks. Manufacturer: Elettroplast in Firenze, Italy (company doesn't exists anymore). {PO} |

| 39 | Bakelite outlet designed to be used at a position somewhere between plug and connector of a flex cord. Brand name: Gebrüder Merten in Gümmersbach (east of Cologne). The MPAD mark has a Bakelite code S. Letter codes have been used from the mid 1920s to - probably - early 1950s. The specimen shown is probably made in the 1950s. {WN} |

|

|

|

| 40, 41 |

Plug made of beech wood. Steel pins are fixed in a fibre plate. Most wooden plugs were made in the early days of home electrification. However, the 1943 stamp inside the plug indicates that it is (German?) made in war-times, a period when there was a severe shortage of nearly everything. {RH} |

| 42 | Another example of a wooden plug made in,

or shortly after Wold War II. {RH} |