|

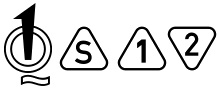

Bakelite molding marks used by MPAD and DAMW |

info page |

|

| Examples

of MPAD marks found on plugs, with codes that identify the press work3

(top)

and the pressed

material (bottom). |

| a |

34 |

Siemens-Schuckertwerke, Berlin |

S4 |

Phenol-formaldehyde resin (Bakelite)

reinforced with sawdust |

| b | 39 | Dr. Deisting, Kierspe |

1 | Phenol-formaldehyde resin with anorganic

(mineral) filling agent (not specified) |

| c | vF | Hugo Burgmaier, Schmiechen |

31 | Phenol- or cresol-formaldehyde resin

reinforced with sawdust |

| d | F2 | Franz Stauch, Unterrodach |

1 314 |

not listed by Oburg5; probably

the code has to be read as 131 |

| e | 95 | Erich Jäger, Homburg |

131 | Urea-formaldehyde reinforced with organic

fibres |

| f | 67 | ABL-BEZEG, Lauf bei Nürnberg |

131 31 |

Code that may indicate that a mold is used

for 31 or 131, depending on batch |

| g | MU | Maehler & Kaege, Ingelheim-Rhein |

51 | Urea-formadehyde reinforced with cellulose |

| ↑ |

23 | Busch-Jaeger, Lüdenscheid |

31 |

| Notes 1 Bakelite is a registered trademark of phenol-formaldehyde resin made by the Bakelite GmbH in Erkner near Berlin (after WW II in Iserlohn; company is now part of Hexion GmbH). Other companies that used comparable resins had to use other names, but the name Bakelite has become generic name for phenol- and urea-formaldehyde resins. Phenol-formaldehyde objects have a dark colour, black or dark- brown, occasionally with a reddish shade; see plug above. Urea-formaldehyde resins have large spectrum of more bright colours; see examples below.  |

2 Although MPAD ended testing of Bakelite products early 1960s, molding mark can also be found on plugs and socket made in the 1970s. Making molds was expensive and they have often been used as long as possible, also for modern thermosetting polymers that were used from the 1960s, see image below of an appliance connector made in the 1970s-'80s. 3 Most manufacturers had their own press work facility, but production of casts could have been contracted out. In such cases the MPAD code corresponds to the company that made the casts. 4 S is the most commonly used code on plugs and sockets made in the 1930s. Code 1 is rarely used; 31 only occasionally. Bakelite plugs and sockets made from 1950s have nearly always a 1 in combination with a 90 degrees rotated 31 code 5 Wilhelm Oburger, Die Isolierstoffe der Elektrotechnik. Springer Verlag, 1957. Page 256, table 10-9. Links to lists with MPAD codes: 1938 list, 1954 list, and a not dated list with some more codes. |

DAMW molding marks  TLG quality marks Q = top quality S = very good quality * 1 = good quality 2 = acceptable quality ** * : used until 1960, then S merged with Q ** : abolished in 1970 |

Marks on plugs made

in the German Democratic Republic In the German Democratic Republic (DDR) product tests were introduced in 1950 by the German Organization for testing of materials and goods (Deutsches Amt für Material und Warenprüfung, DAMW). In 1973 it became the Organization for standards, measure and testing of materials (Amt für Standardisierung, Messwesen und Warenprüfung, ASMW). In 1990 ASMW became a part of the Deutsche Institut für Normung (DIN). Two types of marks can be found on Eastern German products: DAMW molding marks (Überwachungszeichen für Formmassen). Molding marks were used for casts made of Phenoplast (phenol based resins) and Aminoplast (urea based resins). The name Bakelite was not used in the DDR. Left code identifies the press work. For example: N04 = VEB Elektroinstallation Sonderhausen (Thüringen). N06 = VEB Elektroinstallation Ruhla (Thüringen). N25 = VEB Elektroinstallation Kranichfeld (Thüringen). Right code indicates the resin used. No. 31 = phenol-formaldehyde resin, reinforced with sawdust filler. Designs 'b' and 'c' were most often used. Lists of DAMW codes for companies and types of resins (Duroplast and Aminoplasts) can be downloaded as pfd's. TGL quality marks (Gütezeichen der DDR). The quality of products was tested according to the Technical instructions on quality and terms of delivery (Technische Güte- und Lieferbedingungen, TGL), comparable to DIN standards. The quality was among others normative for the price level. Top quality was mainly used for export to western countries; a source of hard currency. |

|

Plastique Français

marque de Qualité. Molding marks used in France from 1946 - 1960s. Information is given on the French manufacturers page. |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |