|

GRIMMA industrial

3-phase 16A and 25A sockets and plugs |

IEC 60309 |

| Despite not being a member of the IECEE,

three-phase industrial sockets and plugs, fully compatible with CEE 17,

have also been made in the former German Democratic Republic. The VEB Elektroschaltgeräte Grimma was the designated manufacturer of 16A, 32A and 63A sockets and plugs. The company used GRIMMA as trade name; see Manufactures for details. Production started in the 1980s and ended after the reunification of East and West Germany in 1990. |

|

|

|

|

|

|

| 1, 2 |

16A-6h

380V three-phase socket with neutral and protective earth contacts.

Keying, red color and 6 hour position of the earth contact is in

line with CEE 17 (IEC 60309) standard. The grey cylindrical block

with pin contacts (image no. 2) has a N46 / 150 DAMW molding mark.

N46 = company code given to VEB Duroplastwerk in Neusalza-Spremberg

(Sachsen); Grimma has contracted out housing production to this

company. 150 = a melamine formaldehyde resin. {PM} |

| 3,

6 |

Wiring

shows a detail unknown to CEE sockets: neutral and earth contacts are

interconnected. The enlarged image (no. 6) suggests strongly that the

copper strip is factory made. See image nos 7-10 for additional

information about earth connection of Grimma three-phase plugs. |

| 4 |

Information given on

housing. Triangle with 1: TLG

quality mark,

1 = good quality. Square inside another square: symbol used for

Class II double insulated electrical appliances that does not require a

protective earth connection. It is not clear why the socket has a Class

II mark. IP43: 4 = protection against ingression of particles ≥ 1 mm; 3

= resists spaying water, also indicated by a triangle with single

droplet. IFD 16: probably a code used by Grimma for 16A industrial

three-phase sockets. Connector plug no.9 has code IFK 16. |

| 5 | The socket cap shows the GRIMMA logo and

an additional, circular logo with "MARS". The significance of MARS is

unknown. |

|

|

|

|

|

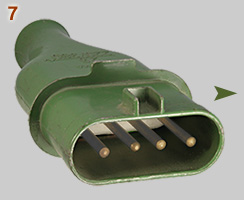

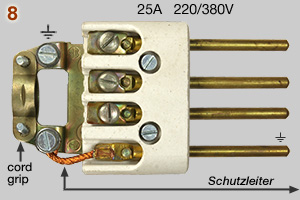

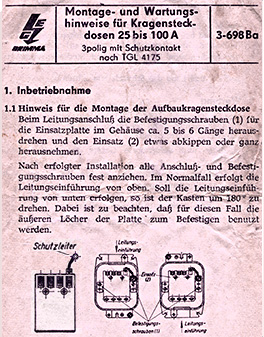

| 7, 8 |

Grimma

25A

3P+E 220/380V plug. The green cast iron housing has a protective rim.

Plug has three line pins (R1, S2 and T3). and an earth pin

that is connected with the brass cord grip by a copper wire

(Schutzleiter, see instruction manual). Two screws (not visible)

connect cord grip with cast iron housing. Although the most obvious

wiring

would consist of four wires: 3x line + earth, but an additional fifth

(neutral) wire has also been found; see wiring

of extension cord no. 9. {PM} |

| 9,

10 note |

Five wire extension

cord with red 16A-6h 3P+N+E 380V connector plug (IFK 16) and green cast

iron 25A 220/380V four pin plug (identical to plug no. 7.

{PM} In contrast to socket IFD 16 (image no 1) contacts for N and E pins are not interconnected by a copper strip. Each of the five wires of the extension cord are connected to both IFK 16 and to the 25A plug, Image no. 10 shows that the yellow/green earth wire is connected to the cord grip top screw. The black neutral wire is connected to the cord grip bottom screw. This means that E and N are interconnected. Peter Martin, donor of most of the DDR material shown on the Plugs and Sockets website explained that a notorious shortage of copper triggered manufacturers and users their ingenuity. A three phase current motor do not need a separate neutral connection because of a balanced load between the three phases. Neutral is free of electric current and under normal conditions a N-E interconnection is no problem. Producing both four pin (3xL +E) and five pin (+N) sockets and plugs is not strictly necessary. Extension cord no. 9 could have four wires, but the use of a - by chance - available five wire cord is better than buying an new, expensive four wire cord. |