|

Origin of Schuko® plugs and sockets |

CEE 7/4 |

Classic Schuko |

info page |

|

Origin of Schuko® plugs and sockets |

CEE 7/4 |

Classic Schuko |

info page |

| The origin

of Schuko® by Reiner Hahn The text below is free of copyrights, if author and source (Digital Museum of Plugs and Sockets) are mentioned clearly. Text is also available as pdf. Schuko is a registered trademark of the SCHUKO-Warenzeichenverband e.V., Bad Dürkheim, Germany1 |

|

-1-

In the years after WWI

the spread of electricity rapidly increased in Europe. As a result life

became more comfortable. But soon also the number of

accidents and fires caused by electricity increased.

Often incidents were induced by inadequate installations and bad accessories. Especially in domestic use the absence of adequately protected appliances and poorly designed plugs and sockets were a constant source of danger. But if someone is working with electricity in this way, just a little carelessness or tiny stupidity could entail serious consequences - sometimes even the death penalty. In commercial use of electricity, earthing and other methods of securing were used since the late 19th century. But only in very rare cases also appliances were secured in homes. If someone wants his domestic appliances to be safer, there were two different opportunities: → |

-2-

|

Fig. 1.

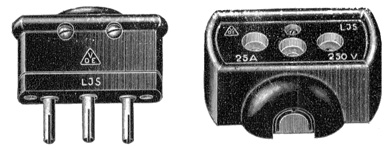

Three-pin, polarized plug and socket system without protection against contact with fingers. Comparable design have been made by various manufacturers since about 1900. Variants were offered from 6 up to 25 Amperes. It was primarily used to connect commercial applications needing three-phase AC. The illustration is taken from a 1930 wholesaler catalogue. Shown is a design by Lindner & Co., Jecha-Sondershausen (Thuringia, Germany). |

|

|

-3-

Since there were no

earthed plugs and sockets specifically made for domestic use, systems

originally intended for commercial three-phased AC were applied. Very

dangerous, if someone misused a socket.

The first earthed plug and socket system exclusively designed for domestic purposes, was presented to the public on a fair in Leipzig in August 1925. Inventor was Albert Büttner, founder and owner of the ABL-company (Bayerische Elektrozubehör A.G. / Lauf a.d. Pegnitz). The concerning patent DRP No. 489,003 was filed in January 1926. The still existing ABL Company was mainly producing appliance couplers at that time. Small appliances like flat irons and coffee makers were just simple metal-cased constructions without a switch. Since the appliances became very hot usually the wall-plug was used to start or interrupt operation. Quite often the user received an electric shock while doing this, because sometimes sparks emitted. Common domestic plugs and sockets had no adequate touch guard and were not earthed. |

-4-

Earthed appliance couplers were already

introduced in Germany in the

early 1920s (see DIN VDE 4990).

These couplers were not polarized, so a

three-wired cord was necessary. The couplers had outer lying

earth-clips in combination with a metal case surrounding and protecting

the connectors inside. When plugging, the earth clips get in contact

with an open metal box surrounding the connection pins of the appliance.

Albert Büttner just transferred that basic idea onto a plug and wall socket. The case of the plug was an earthed metal shell and two earth-clips were assembled inside the socket (fig. 2). Not quite new, but extremely good was the idea of recessing the socket to prevent contact between fingers and the pins of the plug while inserting. But also insuring this way the earth-clips will get in contact first, before the pins. Details are shown on a separate page. The ABL construction was not really successful on the market, because at that time it was not required to earth appliances at home. And the price of the cord – not even including the special wall socket - was about double of a normal unearthed one. |

|

|

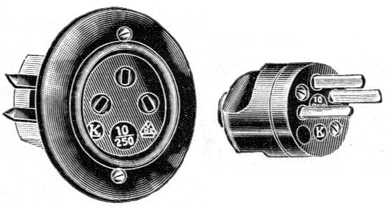

Fig. 2. Early earthed appliance cord and wall socket. The illustration is taken from a 1928 appliance catalogue of the AEG Company in Berlin. They offered it to their customers as a “Küchenschnur” (kitchen-cord). This surely is a variation of the 1926 Büttner-patent. The wall-plug (right) has a flat form like an appliance coupler (left) and the connections for the pins and the earth-clips are assembled in one line inside a metal-cased socket. The museum collection has a similar appliance coupler (see ABL plug no. 13). The Büttner patent originally showed a plug with a circular base and the earth-clips assembled in a 90º angle rotated from the line of the connection holes in the socket. |

|

|

-5-

In 1927/28 finally a

commission was formed. The increasing number of accidents made it

essential to revise the German rules and norms for the construction and

testing of installation material up to 750 Volts (KPI 1928 –

Vorschriften, Regeln und Normen für die Konstruktion und Prüfung

von Installationsmaterial bis 750 V Nennspannung). Included in

the process

of formulation were the VDE (Association of German Electricians), fire

and accident Insurances, leading Installation makers and power suppliers2

Some important new standards of KPI 1928 relevant to 250 V plug and

socket devices were:

• Dangerous areas have to be equipped with earthed installation3. • No more securing of appliances with two-pin polarized plugs and sockets. • All kind of sockets have to be made for at least 10A. • Earthed sockets are not allowed to accept common unearthed plugs. • Unearthed sockets have to accept earthed plugs4. Fig. 3. A domestic variant of HNA that has three flat pins instead of round ones. Although it was not fully according to the KPI 1928 standard, HNA was offered until the 2010s. It always have served a niche market, because it had no touch guard and it was limited to 10A AC. Illustration has been taken from a 1930 wholesaler catalogue, showing an example made by the Leopold Kostal Company in Lüdenscheid, Germany. |

-6-

After introducing KPI 1928 many companies

started to develop new

earthed plugs and sockets for domestic tensions up to 250V5The specifications of KPI 1928 provided a framework that allowed only a small number of solutions. The claim that an earthed socket should not accept an unearthed plug excluded many systems based on a three-pin connection. For example HNA (Handelsschiff-Normen-Ausschuss), a system especially created for naval use. But HNA-sockets also accepted common unearthed plugs with 19 mm (ca. ¾”) pin spacing and HNA-plugs were not suitable for common sockets. Still today HNA is one of several plugs and socket systems used on ships worldwide. Fig. 3 shows a domestic HNA variant.  Click

here for HNA examples in the museum

collection.

|

|

-7-

In homes plugs and sockets

are also used by young children and sometimes rather clumsy people.

From the history of accidents engineers meanwhile knew that even if pin

diameters and pin spacing are different, some users will try to insert

common unearthed two-pined plugs into earthed three-poled sockets.

Connecting a 2-pin plug to power and earth socket contacts would cause

a short circuit or even more dangerous situations.

Such mistakes are not possible if unearthed plugs do not fit in earthed

sockets.

The condition that unearthed sockets have to accept earthed plugs was introduced for reasons of economy. The principals of KPI 1928 had the opinion that not every room of a house needed the more elaborated earthed sockets. But this condition also made it almost inevitable that new earthed plugs would be of a round shape and of about the same size than common ones. Fig. 4. An early domestic plug and socket system with earth-plates. At first sight it looks like Schuko. But a later Schuko-plug would not fit into it, since the notches and grooves are rather different. This illustration quite likely shows the “Delta”-System of 1929 by the Siemens-Schuckertwerke A.G. in Berlin. The Delta-system was offered for just a very short time. Source: Das elektrische ABC by Dr. Ing. Herbert F. Mueller, Moritz Krayn, Technischer Verlag GmbH, Berlin,1930. |

-8-

Many engineers had the

opinion, unlike the creators of HNA, that the basis of common plugs - a

circle with a diameter of 36 mm (ca. 1⅜”) - was too small to

for more than two pins. Pins would be too close to

each other. This was understandable, because at that time many houses

were

supplied with DC power and arc formation is more prominent with DC than

AC. To

prevent limitation to just 6A DC, most of the following

constructions were based on the idea of Albert Büttner, using an earth

connection on the outside of the drum area of the plug. See for example

fig. 4.

|

|

-9-

The system that showed the final solution

of Schuko for the first time was developed by the Siemens-Schuckert

Company in Berlin-Siemensstadt. The old established firm was working on

that specific problem very intensive since 1928. Already in 1929 a

Siemens catalogue (Siemens-Schuckert Werke, Sammelliste Sep 1929,

p.381) showed an earthed system which was quite close to the final

solution of Schuko.

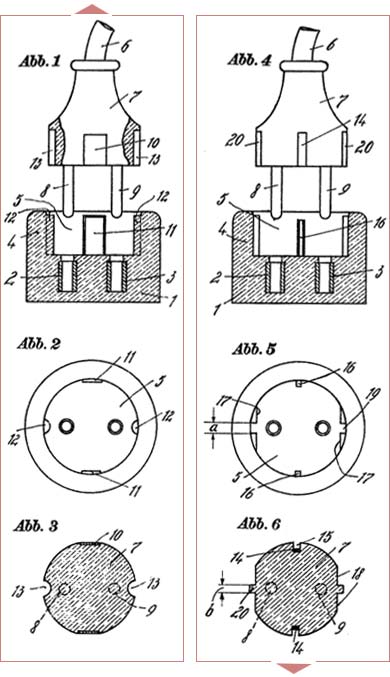

The patent of the ultimate version was assigned to Wilhelm Klement a leading engineer and authorized representative of Siemens (DRP 567,906, filed on the 24th of December 1929)6. This was not the first patent about earthed plug and socket devices by Klement. Already on the 9th of October 1929 he had applied for another patent (DRP 530,143). In this forerunning patent he had taken over the idea of Albert Büttner to use earth-clips inside a recessed socket, but he also added notches inside to prevent the insertion of an unearthed plug7. The really new part of his invention was a plug with recessed contact strips for earthing, arranged in two grooves on the cylindrical outside area of the plug (see fig. 6, Abb. 6). Plugs designed by Büttner and others had earth strip at the plug surface. If a plug was used with an unearthed socket, and an appliance connected to it (or its cord) was damaged, there was a risk of earth clips under tension, giving the user an electrical shock if the the freely accessible earth clips are touched. The final solution of the second patent showed a variation of the grooves and notches to prevent insertion of a common plug or insertion of plugs with earth-plates, as they had already been offered by Siemens (!). Klement mentioned in the patent that there are surely even more variations possible to create plugs and sockets to separate them for the various power tariffs offered by the suppliers. Finally this was done in the 1930s with different shapes of the pins (see for example museum plug no. 1). Fig. 5 The final version of Schuko. Excerpt taken from DRP 567,906 (DE000000567906A in DPMA-Depatis)* by the Siemens-Schuckertwerke A.G. and Wilhelm Klement; filed on Dec. 24, 1929, granted on Dec. 22, 1932. Note that Abb. 1-3 refer to the earlier version shown in fig. 4, while Abb. 4-6 refer to the final version of Schuko socket and plug as shown in fig. 6. |

-10-

|

|

-11-

In 1930 the Rheinisch-Westfälisches

Elektrizitätwerk A.G. (RWE), a major power supplier in the western part

of Germany, took over the final solution of Siemens/Klement as their

system of earthed plugs and sockets, prescribed to their customers8.

This helped the new system to sweep the market of 250V earthed plugs very fast. Already in 1930 it was provided by several makers of installation material. They were assembled with three different pins-shapes for different power-tariffs: lighting, domestic appliances (kitchen and heating) and commercial purposes. The RWE-Schuko plug had pins with a diameter of 4.8 mm and was authorized for a maximum of 10A DC or 15A AC. It had a long and slightly conic grip with slip-proof ribs on the surface (fig. 6). Possibly not the most elegant design, but safe and convenient in use. They were made in large numbers until the 1960s. Until today Schuko has not changed substantially from the solution of Siemens-Klement. A 2016 plug will fit into a 1930 socket and will fulfill it´s simple task properly. Schuko became necessary because of the strong spread of small moveable electrical appliances in domestic use. And it became possible through the creativity of several inventors and also huge progresses in manufacturing and plastics engineering in the 2nd half of the 1920s. |

-12-

Fig. 6. The classic RWE-Schuko plug. It might be tempting to speculate about the best option for domestic earthed plugs, a system with earth clips or an earth pin. There are advantages and disadvantages for both. Often mentioned is the disadvantage of Schuko being a not polarized system. But there are hardly any applications in domestic use below 15/16A that really need polarization. The fact that Schuko is used in 70 countries around the world proves the success of the earth clip system. |

|

-13-

Footnotes.1 Schuko is an

abbreviation for the German word Schutzkontakt (Protective Contact). The

term itself was created in the 1920s. The roots are not fully clear.

According to the Schuko-Waren- zeichenverband e.V. the AEG Company in

Berlin was in 1930 the first proprietor of trademark

rights. But it´s

sure, that originally the term was used for another technical device.

In the mid-1930s it was carried over to this special plug-socket system.

Also other plug and socket systems with an earth pin or earth clips often were named Schuko from the 1930s until the 1960s. See museum page on pre-IEC 60309 plugs and sockets (nos. 7-10). 2 Not involved were authorities and other public bodies. In Germany the electrical industry managed - unlike in France and Great Britain - to keep the government largely out of their business. In former times the principals considered this as one of the reasons for the worldwide success of their branch. One of the harmful consequences of self-regulation was that the discussion about earthing in domestic surroundings lasted for many decades. Another consequence is that all kinds of rules and norms made by specific professional associations never had the legal status of laws in Germany. Still today it is just voluntary to note them. Usually they are followed quickly, because jurists regard them as the current state of technology. But in former times it often needed years until all products of all makers were according to the actual standards 3 This was not really new - and might have a real progress in safety. But still the 1930 rules of the VDE did not explain clearly in which parts of a building dangerous conditions can be present. Humid and wet surroundings should be equipped with earthed installation in any case. But - not like others - kitchens and bathrooms were not explicitly named as such areas! (V.E.S. 1/1930, §§ 2m, 3c, 31; V.E.S. (Vorschriften für die Errichtung von Starkstromanlagen). The first version became valid after 1895. Nowadays these regulations are part of DIN VDE 0100. The accredited remarks about the 1930 rules explained that in every individual case a skilled person had to decide. Recently this could be also the installer. It was also mentioned that in living areas and offices dangerous situations occur, because earthed hot water radiators and telephone systems are present together with unearthed electrical installations. But this was not enough to classify them as potential dangerous areas. It lasted until the 1960s that earthed sockets and earthed appliance connections were required in every room of a house in (West-) Germany. |

-14-

4 This was not

a regulation of KPI 1928, it was a postulation from users of earthed

plug-systems for reasons of economy. Since 1924 it was required by the

VDE to earth electrical installations in commercial and agronomical

areas (Vorschriften für die Errichtung und den Betrieb elektrischer

Starkstromanlagen nebst Ausführungsregeln, July 1924, §3-d). Often the

same electrical appliances were used in small business premises and

domestic areas as well. For cost reasons the users wanted one plug

systems suitable for both applications. Since this discounts the idea

of safety and permanent earthing it did not became part of KPI 1928,

but it had been taken into account during the development of new

earthed 250V plug systems.

5 The AEG Company in Berlin applied for a patent on an earthed plug-socket system for domestic tensions in April 1927 (DRP No. 490,086). It was already according to the main rules of KPI 1928 and was even polarized. But it seems the system was never offered on the market. Maybe it was not even produced. 6 Wilhelm Klement was also a member of the VDE commission for installation-material (source: Membership list of the VDE, autumn 1925). 7 There was even a 3rd patent by Siemens at this time. Another engineer was working on the same issue at the same time. Joseph Limbach applied for a patent on the 7th of December 1929 (DRP No. 547,367, granted March 1932). In his solution he proposed a kind of collar above the open earth-contacts to prevent touching while inserting. 8 Since about 1890 it was common practice in Germany that power suppliers prescribed special kinds of installation and material to the costumers and installers in their service area. In fact, it had been the power suppliers - not the VDE - that formulated first rules and norms about the quality of electrical installation in Germany. The RWE decision for the Siemens-Klement system was surely significantly influenced by Otto Heinisch and Anton Riedl. Otto Heinisch was administrative director at the RWE branch office in Kleve. Also Anton Riedl was working there as an operating manager. Both were very engaged in bringing more safety into the utilization of electricity. In 1924 they developed the very first Earth-Leakage-Circuit-Breaker (ELCB). An invention that undoubtedly saved many lives up to the present day. * Note re. DEPATISnet Einsteigerrecherche: Veröffentlichungsnummer = DE000000567906A Delete A47J31/24 in 'Alle IPC-Felder' and click button 'Recherche starten' Origin of Schuko®, by Reiner

Hahn; February 9, 2017

|

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |