|

Domestic Plugs and Sockets Notes on Diversity and Safety |

info page |

| Diversity,

illustrated in panels 1 - 6. A conservative estimate shows that worldwide at least 60 different types of plugs are used in homes and offices; some types are more common than others. If you add heavy duty and three-phase plugs, used in workshops etc., then the variety is much larger. Factors that explain plug diversity are: • Home electrification, started by initiatives of locally operating electricity companies, created a market for electrical accessories. Companies often produced their own designs. Ingenuity and competition were the germ of diversity. • Differences with respect to current and voltage and the need for a protective earth connection asked for different types of plugs. → Read more about current and voltage at the foot of the page. • The demand of special types of plugs meant for specific purposes only, has enlarged the diversity in plugs even further. For both developers and end users of plugs it became clear that harmonization in plug design would be desirable. Manufacturers and/or authorities established standardization committees, or broadened the scope of already existing committees. |

In

principle standardization is country specific, but many countries have

chosen to adopt one or more of already existing standards. In 1986 the International Electrotechnical Commission launched new standards for 230 and 115 Volt household plugs, intending a worldwide use. Up to now only Brazil and South Africa have taken initiatives to replace their multiple standards for the global IEC 60906 standard. It will take at least decades to achieve that goal. Safety aspects, illustrated in panels 7 - 11. Over many decades the safety of plugs and sockets have improved significantly. Step by step safety features have been introduced in revisions of a particular plug or socket standard. Sooner or later, most improvements have been incorporated in other country standards for domestic plugs and sockets. Reducing potential danger caused by inquisitive or careless use has always been important safety issues. Other technical changes enhance the connection between socket contact and plug pin. Most examples shown below are currently used devices, but some classic models are shown when relevant. Museum pages on classic material show more diversity. |

|

1.

Initially,

electricity in homes was only used for illumination. Homes were hard

wired. By the late 19th century portable lamps and electrical

appliances became available. They generated the need of plugs and

sockets. Not surprisingly, the first plugs were lamp holder

screw-in models (a), but quite soon more practical, separate sockets

and

matching plugs were developed. In the US, Hubbell's straight-blade plugs became the preferred model (b), while in Europe most plugs had round pins. In continental Europe, in particular Germany, there was quite soon a preference for plugs with 4 mm pins, spaced out by 19 mm (three-fourth of an inch) (c). |

|

2. From

the early days of domestic electrification both 110 and 220 volt

were offered (either AC or DC). In many countries

different

plugs still exist for a specific voltage and/or maximum allowed

current in amperes. Left pair of plugs: Old British 2-pin BS 372 Part 2. Right pair of plugs: U.S. plugs according to NEMA 1-15 and NEMA 2-20 specifications. Find other examples at pages on Australasian, BS 546, Italian, North American and Swiss plugs. |

|

3. An

even wider range of types arose when plugs with a separate earth

connection were developed, first in the 1910s for technical equipment

and

from mid 1920s also for domestic use. Shown are examples of some

current plug standards. Green arrows point to earth pin, clip or

contact. Three matching sockets are shown below. a. British BS 546; b. German CEE 7/4 (Schuko); c. U.S. NEMA 5-15P; d. Swiss SN 4411011; e. British BS 1363; f. Australian AS/NZS 3112; g. Danish DS 107-2-D1; h. French CEE 7/6.  |

|

4. Flex

cords with special appliance

connectors were introduced as soon as the market for electrical

household equipment started to grow. Three examples are shown. Left: pairs of single connectors were popular from late 19th century until 1920s. Middle: connector that combines both contacts in a single casing. Clips allow earth contact. 1920s - 1970s. Right: modern connector according to IEC 60320 standard. Find many more examples on Appliance Connector pages. |

|

5.

Worldwide there are 13 standards for domestic plugs and sockets (number

depends on criteria used). Beside, there are types that deviate - on

purpose - from common plugs. They are meant for

special applications only; for example: a. Electronic and medical equipment using a local network that protects against voltage fluctuations, and/or require uninterrupted power supply. b. Equipment that need a deviant voltage and/or direct rather than alternating current. Confusion between standard and alternative network has to be avoided. c. Special plugs if the possibility of reversing line and neutral poles has to be impossible (applies in particular to countries that use Schuko or Italian type of plugs). d. Locking devices that protect against unintended breaking a plug-socket connection. Special plugs may have deviant pin shapes, see panel 8. See pages on Uncommon plugs for more examples. |

|

| 6.

Irrespective of the type (standard) of a socket, two distinct models

exist: surface sockets (a, b) and flush sockets (c, d, e). a. Australasian type 10A socket with fully flat top. b. CEE 7/1, not earthed socket with shallow (5 mm) recess. CEE 7/2 plugs (f, g) fit in this socket or its flush equivalent. c. British BS 1363 socket with fully flat top and switch. d. North American 15A-125V dual socket; each pin inlet has a 3 mm recess to facilitate pin entry. e. Swiss 10A socket with a safe 17 mm deep recess*. |

In

principle two models of plugs exist. They differ in respect to the cord

entry, which is at the top of plug (f), or at the side (g). Side entry is regarded as most safe, because it is nearly impossible to retract a plug by tugging on the cord, instead of grabbing the plug. * Note that some standards allow only sockets with a recess. For example CEE 7/3 (Schuko), Swiss SN 441011 and IEC 60906. British and Australasian sockets never have a recess. |

|

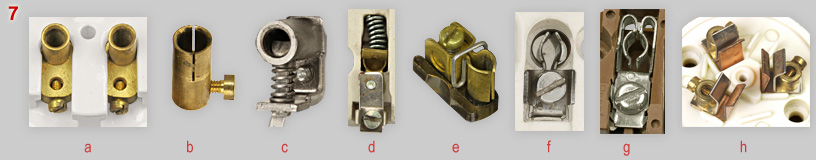

| 7.

A stable contact between socket and plug, over a sufficiently large

area, asks for socket contacts and/or plug pins that have certain

degree of flexibility. Various socket contacts are shown here; see

panel 8 for pin types. a. Initially contacts were simple tubes. Matching plug pins have to be able to adapt their diameter (see pin 8e). b. Soon, contacts were used that have two incisions. They create some flexibility. c. Non-flexible contact with a spring loaded rod that presses the pin towards the tube interior. Danish, 1950s design by LK. |

d. Half round

contact with spring loaded brass plate to provide stable contact. Found on Russian socket. e. Flexible contact found on older Ébenoďd (France) sockets, but also used by NIKO (Belgium) and others. f. Flexible contact on former Eastern German (DDR) sockets. g. More modern type of flexible contact. Several variants exist. Shown example: Presto (Gebr. Vedder, Germany), 1980s. h. Contacts for straight blade pins. This simple but efficient example has been found on Australasian socket 6a. |

|

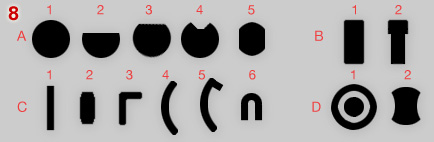

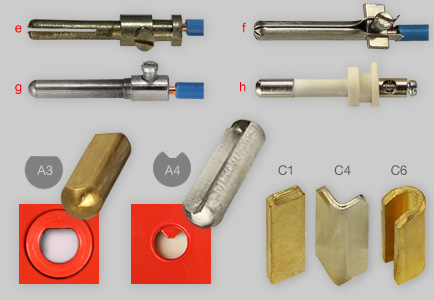

8. Plug

pins exist in many shapes and sizes*. Models A, B and C can be found

on current domestic plugs, including plugs for special purposes; see

panel 5. A1-5. Round pins and derivatives. B1, 2. Rectangular pins. C1-6. Straight blade pins and derived curved shapes. D1. Concentric 2-pole arrangement; no longer used for domestic plugs [link]. D2. Pin shape designed when different tariffs had to be paid for home lighting and domestic appliances [link]. Images e-h show modifications of round pins. e. Most plugs made in the first half of the 20th century have partially split pins. They provided sufficient variability in pin diameter for making good connection with socket contacts as shown in 7a, 7b and similar. f. Cheap pin made of a curled up sheet of metal. They have been made by a few companies in 1950s-'60s. g. Solid pin, first produced in the late 1920s when socket contacts were sufficiently flexible. Now the standard pin. h. Partially insulated pin. Common on plugs that are used with not recessed sockets. For example Australasian (6a), BS 546 (3a) and BS 1363 (6c). Shown is a Euoplug pin. * Pin size varies. The higher the maximum allowed current, measured in amperes, the larger round pin diameter or flat blade width. |

|

|

9. Three safety features: socket with shutters (a-c), provision to ensure that earth pin makes contact first (d-e), and plug pins with insulating sleeves (d-f). a-c. Shutter system designed by MK Electric in 1928 and still in use. A shutter covers line (L) and neutral (N) contacts (a, b). When inserting a plug, the long earth pin pushes the shutters aside (c). Other systems in which simultaneous insertion of L and N pins opens shutters exist also, see socket shutter page for examples. d, e. Most standards stipulate that protective earth contact has to be made first. Methods to archive this are: earth pin is longer than L and N pins (d), or socket earth contact has a protruded position (e). Also the earth clips of Schuko plugs and recessed sockets makes contact first. f. Two plugs; their (flat) pins are just in contact with socket contacts. Pins that lack sleeves can be touched with a metal object or fingers. Note that earth pins never have sleeves (see 9d, e and f). |

|

10.

Preferably, cords have to be fixed firmly to plugs. Some people remove plugs by tugging on the cord; a dangerous practice. One or more wire connection may break. Therefore many plugs are provided with a cord grip. a. Cord is squeezed by the two halves of a plug. A method that was mainly used on older (Bakelite) plugs.* b. Cord is fixed by a metal or plastic brace. The most common method found on modern plugs. c. Anchorage by two angled plastic plates that prevent cord retraction. Typical method on BS 546 and BS 1363 plugs. * page on classic German plugs show alternative methods. |

|

11.

Distribution boards in homes have fuses or circuit breakers to protect

against overcurrent, but ..... a, b. In the old days of home electrification sometimes, rooms had additional fuse boxes (a), or sockets had an integrated fuse (b) to limit the inconvenience of a blown fuse to a single room or outlet. Both examples are French and date back to the 1950s. c. From 1947 British homes were (re)wired according to ring, rather than radial circuit technique. The associated BS 1363 plugs must have a fuse. The image shows a 13A fuse, the maximum allowed rate. The correct fuse specification depends on the wire diameter of the attached flex cord. The fuse can be replaced by a model rated at 5A or 3A. |

| Notes on different

choices regarding current and voltage When the utilisation of electricity started in the 19th century it was the work of many great inventors and technical pioneers all over the world. New innovators created their own systems. Still today network parameters may differ with respect to using either direct current (DC) or alternating current (AC), an AC frequency of 50 or 60 Hz and electric potential for domestic use of 110 or 220 volt. In the late 1870s Thomas Edison worked on using electric power for illumination of homes. His incandescent lamps worked on 110 volt DC. The relative low voltage was chosen to keep the thickness of copper wires to an economical manageable size. Direct current was at that time the most practical and reliable system of power distribution. However, the main drawback of low voltage DC was the very limited range of transmission - hardly more than 1 km - without too much loss of power. Alternating current was a more promising alternative because it could be increased and decreased by transformers. Electric power can be transported through power lines efficiently at high voltage, which reduces energy loss caused by resistance in wires. At the point of destination power can be transformed to a low voltage, suitable for end-users. In the early 1880s Károly Zipernowsky, Otto Bláthy and Miksa Déri at the Ganz factory in Budapest, Hungary invented an efficient AC step-down transformer, to reduce power to a safe voltage level. A few years later Nikola Tesla invented a step-up transformer that delivered a high output voltage, suitable for transport. Another important improvement was the three-phase transformer, developed in 1889 by Mikhail Dolivo-Dobrovolsky at AEG (Allgemeine Elektricitäts-Gesellschaft in Berlin, Germany). George Westinghouse worked in 1884 on DC lighting systems, but soon he became aware of European AC systems. He imported British transformers and a Siemens AC generator. William Stanley improved the transformers and developed a practical system of high voltage AC transmission that allowed distribution of power over wide areas. In 1886 Westinghouse and Stanley started to install AC-lighting systems. The success of the approach led Westinghouse into a bitter confrontation with Edison. The battle between AC and DC became known as the “War of Currents”. |

Cont.

Electric power distribution by three-phase step-up and step-down transformers has won the AC-DC battle convincingly. It is the worldwide used system for power transmission over long distances. According to calculations made by Tesla, the best frequency of an AC generator is 60 Hertz (cycles per second). This is still used in North America. AC transformers developed by AEG in Germany were fixed at 50 Hz, because it fits the metric standard. In Britain different frequencies have been used, but after World War II 50 Hz became the standard frequency. Japan uses in different regions either 50 or 60 Hz. Another difference that still exists is the choice of ‘domestic’ voltage: 100-120 volt versus 220-240 volt. Edison preferred 110V DC and also the AC networks build by Westinghouse offered 110 volt to end-users. This low voltage was regarded as acceptable safe, an issue that made sense because in the early days of electrification bare or poorly insulated wires were often used. 110 Volt is fine for home illumination, but it could deliver insufficient power when the number of more demanding appliances increased. Network stability was in danger. Already in the early 1900s reliable material and clear installation procedures became available and several electricity companies in Europe started to offer 110 and/or 220 volt. Nowadays 110 volt is hardly used anymore, except for special applications. Over the last decades voltage in a large part of Europe has been raised gradually to 230V. This harmonisation has resulted in an integrated power network in Europe. The US and Canada were convinced of the necessity to raise voltage, but facing the costs of replacing all appliances it was decided to introduce nationwide a technique that offers both 110 and 220 volt to each home. This split-phase wiring technique is explained on another museum page. Source: Wikipedia pages on AC Power and pages referred therein. I am grateful to Reiner Hahn for valuable comments. |

| |

D i g i t a l M u s e u m o f | |

P l u g s a n d S o c k e t s | |